PakAlumni Worldwide: The Global Social Network

The Global Social Network

World Bank Says Pakistan Led South Asian Employment Gains in 2000-2010

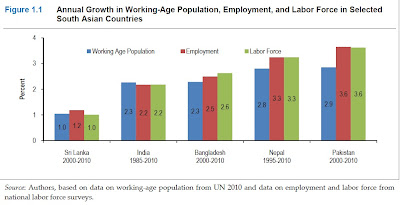

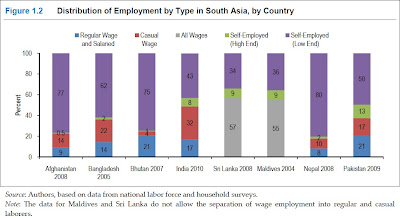

Total employment in South Asia (excluding Afghanistan and Bhutan) rose from 473 million in 2000 to 568 million in 2010, creating an average of just under 800,000 new jobs a month. In all countries except Maldives and Sri Lanka, the largest share of the employed are the low‐end self-employed.

The report says that nearly a third of workers in India and a fifth of workers in Bangladesh and Pakistan are casual laborers. Regular wage and salaried workers represent a fifth or less of total employment.

Analysis of the labor productivity data indicates that growth in TFP (total factor productivity) made a larger relative contribution to the growth of aggregate labor productivity in South Asia during 1980–2008 than did physical and human capital accumulation. In fact, the contribution of TFP growth was higher than in the high‐performing East Asian economies excluding China.

India's labor productivity growth since 1980 has been the highest in South Asia, followed by Sri Lanka and Pakistan. This was particularly the case in India where TFP rose by 2.6% versus 1.4% in Pakistan during this period.

The report argues that South Asia region needs to create a million jobs a month just to keep up with the growth of the workforce. In addition to corruption, conflicts and political instability, the report specifically mentions electricity shortage as a key factor inhibiting job growth in the region. Power sector financial losses across the region are large, resulting from the misalignment of tariffs, the high cost of power procurement, and high transmission and distribution losses. In India the combined cash loss of state-owned distribution companies is more than $20 billion a year, compared with $300 billion of investment needs in 2010–15. The sector deficit in Pakistan is estimated at about $2 billion a year, compared with $32 billion of investment needs in 2010–20.

Increased load shedding in Pakistan alone has cost 400,000 jobs in recent years, according to the World Bank. Although the World Bank report does not address it directly, the anecdotal evidence suggests that almost all of Pakistan's job growth for the decade occurred from 2000-2007 when the economy showed robust gdp growth. During 2000-2007, Pakistan's economy became one of the four fastest growing economies in Asia with its growth rate averaging 7.0 per cent per year for most of this period. As a result of strong economic growth, Pakistan succeeded in reducing poverty by one-half, creating almost 13 million jobs, halving the country's debt burden, raising foreign exchange reserves to a comfortable position and propping the country's exchange rate, restoring investors' confidence and most importantly, taking Pakistan out of the IMF Program. Contrary to its public criticism of the Musharraf-era economy, the preceding facts were acknowledged by the current government in a Memorandum of Economic and Financial Policies (MEFP) for 2008/09-2009/10, while signing agreement with the IMF on November 20, 2008.

It's important for Pakistani government to seriously address the energy and security crises to restore investor confidence and bring back the strong economic growth necessary for creating millions of jobs for its growing youth population entering the workforce. The consequences of inaction on this front would be far more disastrous than the negative effects of the current Taliban insurgency.

Related Links:

Haq's Musings

More and Better Jobs in South Asia

Incompetence Worse Than Corruption in Pakistan

Pakistan's Circular Debt and Load Shedding

Pakistan Planning Commission

US Fears Aid Will Feed Graft in Pakistan

Pakistan Swallows IMF's Bitter Medicine

Shaukat Aziz's Economic Legacy

Pakistan's Energy Crisis

Karachi Tops Mumbai in Stock Performance

India Pakistan Contrasted 2010

Pakistan's Foreign Visitors Pleasantly Surprised

After Partition: India, Pakistan and Bangladesh

The "Poor" Neighbor by William Dalrymple

Pakistan's Modern Infrastructure

Video: Who Says Pakistan Is a Failed State?

India Worse Than Pakistan, Bangladesh on Nutrition

UNDP Reports Pakistan Poverty Declined to 17 Percent

Pakistan's Choice: Talibanization or Globalization

Pakistan's Financial Services Sector

Pakistan's Decade 1999-2009

South Asia Slipping in Human Development

Asia Gains in Top Asian Universities

BSE-Key Statistics

Pakistan's Multi-Billion Dollar IT Industry

India-Pakistan Military Comparison

Food, Clothing and Shelter in India and Pakistan

Pakistan Energy Crisis

IMF-Pakistan Memorandum of Economic and Financial Policies

Tags:

- Attachments:

-

-

WorldBankSouthAsiaJobs.pdf, 1.6 MB

WorldBankSouthAsiaJobs.pdf, 1.6 MB

-

Replies to This Discussion

-

Permalink Reply by Riaz Haq on April 16, 2014 at 10:32pm

-

From VOA report:

The World Bank says that in Pakistan, roughly 70 percent work in the so-called informal sector, a part of the economy that is unregulated and untaxed.

On a good day, Jamil Hassan will have some 15 customers, and earn an average of $8 a day.

Hassan is one of the millions working in Pakistan's informal economy, the mainstay for the country's vast poor. He never went to school. Cutting hair is all he knows.

"I've been doing this all my life," he said. "My father and grandfather did it before me, so this is what I do."

About 40 percent of all workers in Pakistan have no education. Hassan says illiterate people like him will never make enough to be able to save money.

Economist Ali Kamal says the informal economy can be seen as helping the country's overall economy.

"It absorbs a labor who is otherwise unemployed, it provides services at a cheaper cost and cheaper price to the general public, and it complements the formal sector," he said.

Mohammad Naeem works in a modest seasonal wheat mill, when Pakistan's constant power cuts don't grind work to a halt. Naeem says he would like to have his own business. But he doesn't believe in bank loans or in savings.

"I feel that people should not take loans, not owe money," he said. "That is very important. You should only use what you earn."

Kamal says millions of workers like Naeem and Hassan don't pay taxes, meaning less money for an already cash-strapped state.

"If we collect sales tax from all those informal sectors, it may account for four to five percent of GDP, and if we collect four to five percent GDP in sales tax from those informal activities, then we don't have any budget deficit anymore," he said.

But as of now, the informal sector is providing cheaper goods, services and labor to the formal sector. Analysts say Pakistan would have to reform its entire economic structure to change the situation

http://m.voanews.com/a/millions-labor-in-pakistans-informal-economy...

-

Permalink Reply by Riaz Haq on May 26, 2015 at 4:43pm

-

A long tradition in development economics treats manufacturing as special. Some of the development benefits the sector provides rely on large and growing numbers of manufacturing jobs, not just rising levels of manufacturing output. Labor productivity in manufacturing converges rapidly towards international norms. This gives aggregate productivity a bigger boost; the larger the share of the workforce that is in manufacturing, the greater the boost. The more rapid the manufacturing employment growth, the faster workers move out of low-productivity, low-wage agriculture and traditional services.

Unfortunately, cross-country analysis of the connections between manufacturing employment and levels of development has been restricted to OECD countries. This matters because many developing country governments have large programs to stimulate manufacturing activity, on the understanding that jobs and higher incomes will follow. Ambitious job targets are announced - such as 100 million new manufacturing jobs by 2022 in India. These are typically justified with reference to the experiences of earlier industrializers, like Korea and Taiwan. Public budgets, land and labor regulations, and even education policy are being modified to pursue these manufacturing jobs. We can see why developing countries want these manufacturing jobs: our data show that a country’s peak manufacturing employment share between 1970 and 2010 rather than is its peak manufacturing output share, is a much better predictor of its average per capita GDP in 2005-2010. Controlling for peak manufacturing employment shares and the date that manufacturing activity peaked, peak output shares are insignificant predictors of subsequent prosperity. This suggests that manufacturing output matters for prosperity only insofar as it comes with jobs. Moreover, we show that every country that is rich today, by any reasonable standard, had more than an 18-20% manufacturing employment share sometime since 1970.

It is important to note that industrial activity typically grows with income in poorer countries, peaks, and then falls with income and wages in richer (deindustrializing) countries. There are two reasons we think that manufacturing employment-led development is becoming more challenging.

- Labor productivity has risen faster in manufacturing than in the wider economy. Higher levels of manufacturing output are now compatible with lower levels of manufacturing employment. Figure 1 confirms this, showing that peak manufacturing employment shares have fallen over time. Peak output shares have not.

Figure 1: Manufacturing Employment Shares Have Declined, Output Shares Have Not

- Manufacturing activity is now more apt to leave for other countries as labor costs rise. Therefore deindustrialization kicks in at lower income levels. Moreover, this premature deindustrialization is more apparent in employment than in output data. Output can be sustained in the face of rising labor costs by replacing workers with machinery.(Arvind Subramaniam and Amrit Amirapu show similar trends in industrial (manufacturing plus mining, utilities and construction) employment using repeated cross-sections of countries.)

Countries still industrialize and then deindustrialize as they become richer. However, industrial employment shares for today’s late industrializers such as China, India and Bangladesh are all below 16%, and on today’s trends seem unlikely to rise much further. Moreover, the per capita income levels at which deindustrialization kicks in have fallen from $34,000 in 1970 to around $9,000 in 2010.

These results urge a balanced approach to industrialization. They confirm that industrialization matters – when it brings jobs; but they also confirm that this is less and less likely to happen. Governments must not neglect manufacturing. Nor can they rely as heavily on it as they once did.

- Labor productivity has risen faster in manufacturing than in the wider economy. Higher levels of manufacturing output are now compatible with lower levels of manufacturing employment. Figure 1 confirms this, showing that peak manufacturing employment shares have fallen over time. Peak output shares have not.

-

Permalink Reply by Riaz Haq on June 2, 2015 at 8:46pm

-

From The Economist Mag: A robotic sewing machine could throw garment workers in low-cost countries out of a job

HUMAN hands are extremely good at making clothes. While many manufacturing processes have been automated, stitching together garments remains a job for millions of people around the world. As with most labour-intensive tasks, much of the work has migrated to low-wage countries, especially in Asia. Factory conditions can be gruelling. As nations develop and wages rise, the trade moves on to the next cheapest location: from China, to Bangladesh and, now that it is opening up, Myanmar. Could that migration be about to end with the development of a robotic sewing machine?

There have been many attempts to automate sewing. Some processes can now be carried out autonomously: the cutting of fabric, for instance, and sometimes sewing buttons or pockets. But it is devilishly difficult to make a machine in which fabric goes in one end and finished garments, such as jeans and T-shirts, come out the other. The particularly tricky bit is stitching two pieces of material together. This involves aligning the material correctly to the sewing head, feeding it through and constantly adjusting the fabric to prevent it slipping and buckling, while all the time keeping the stitches neat and the thread at the right tension. Nimble fingers invariably prove better at this than cogs, wheels and servo motors.

“The distortion of the fabric is no longer an issue. That’s what prevented automatic sewing in the past,” says Steve Dickerson, the founder of SoftWear Automation, a textile-equipment manufacturer based in Atlanta, where Dr Dickerson was a professor at the Georgia Institute of Technology.

The company is developing machines which tackle the problems of automated sewing in a number of ways. They use cameras linked to a computer to track the stitching. Researchers have tried using machine vision before, for instance by having cameras detect the edge of a piece of fabric to work out where to stitch.

The Atlanta team, however, have greatly increased accuracy by using high-speed photography to capture up to 1,000 frames per second. These images are then manipulated by software to produce a higher level of contrast. This more vivid image allows the computer to pick out individual threads in the fabric. Instead of measuring the fabric the robotic sewing machine counts the number of threads to determine the stitching position. As a consequence, any distortion to the fabric made by each punch of the needle can be measured extremely accurately. These measurements also allow the “feed dog”, which gently pulls fabric through the machine, to make constant tiny adjustments to keep things smooth and even.

------

Shoemakers are already using 3D printers, which build up material additively, to make prototypes of shoes. Exotic clothing and shoes made with 3D printers are becoming regulars on the catwalks at many of the world’s leading fashion shows, although the materials they are printed from tend to be various sorts of plastic, which can make the garments somewhat clunky and shoes a bit clog-like. However, researchers are working on ways to print more flexible materials. One such project involves a collaboration between Disney, Cornell University and Carnegie Mellon University. Their 3D printer uses layers of off-the-shelf fabric to make soft objects, such as cuddly toys.

http://www.economist.com/news/technology-quarterly/21651925-robotic...

-

Permalink Reply by Riaz Haq on September 9, 2017 at 11:07am

-

Raghuram Rajan flags India's biggest worry that could cost Modi a win in 2019 elections: Slow Job Growth

http://economictimes.indiatimes.com/news/economy/policy/raghuram-ra...

"Remember that we have what we call the population dividend. A million new people entering the labor force every month," Rajan said. "If we don’t provide these jobs that are required, you have a million dissatisfied entrants. And that could create a lot of social mischief."

Rajan is right in this aspect. India will have the world’s biggest labor force by 2027 and the millennial generation is crucial to anchor one of the fastest paces of economic growth. However, fresh employment opp ..

Under Modi, just over 10,000 jobs a month are being created instead, according to government figures from 2015.

Read more at:

http://economictimes.indiatimes.com/articleshow/60434472.cms?utm_so...

Twitter Feed

Live Traffic Feed

Sponsored Links

South Asia Investor Review

Investor Information Blog

Haq's Musings

Riaz Haq's Current Affairs Blog

Please Bookmark This Page!

Blog Posts

Independent Economists Expose Modi's Fake GDP

Ruling politicians in New Delhi continue to hype their country's economic growth even as the Indian currency hits new lows against the US dollar, corporate profits fall, electrical power demand slows, domestic savings and investment rates decline and foreign capital flees Indian markets. The International Monetary Fund (IMF) has questioned India's GDP and independent economists Professors Arun Kumar…

ContinuePosted by Riaz Haq on January 25, 2026 at 4:30pm

US Immigrant Visa Freeze For 75 Countries: Why Pakistan But Not India?

The US State Department has suspended processing of immigrant visas from 75 countries, including Pakistan but not India. This action followed President Donald Trump's social media post that listed, without context, the percentage of immigrant households from these countries that rely on the US government financial assistance. While Mr. Trump’s post singled out immigrants,…

ContinuePosted by Riaz Haq on January 17, 2026 at 5:30pm

© 2026 Created by Riaz Haq.

Powered by

![]()