PakAlumni Worldwide: The Global Social Network

The Global Social Network

Pakistan Plans to Convert Coal-Fired Power Plants to Burn Domestic Thar Lignite

With a new 330 MW mine-mouth coal-fired power plant in Tharparkar, Pakistan has now reached 990 MW of power fueled by the local lignite. Thar coal production is being expanded and plans are in place to convert three more imported anthracite coal fired plants to burn domestic lignite as soon as its production is expanded and a rail link is completed to transport the fuel to the rest of the country. Plans call for using Thar coal in three coal-fired plants currently burning imported coal: Sahiwal Coal Power, China Hub Coal Power and Port Qasim Coal, each of 1,320MW installed capacity. These power plants may require some limited equipment changes to burn domestic lignite. It is worth noting that Pakistan contributes less than 1% of the global greenhouse-gas emissions. Using the higher polluting domestic Thar lignite is crucial to Pakistan's desperate need for cheap energy to spur industrialization for economic growth without running into recurring balance of payments crises.

|

| Pakistan Electric Power Generation Fuel MiX. Source: Arif Habib |

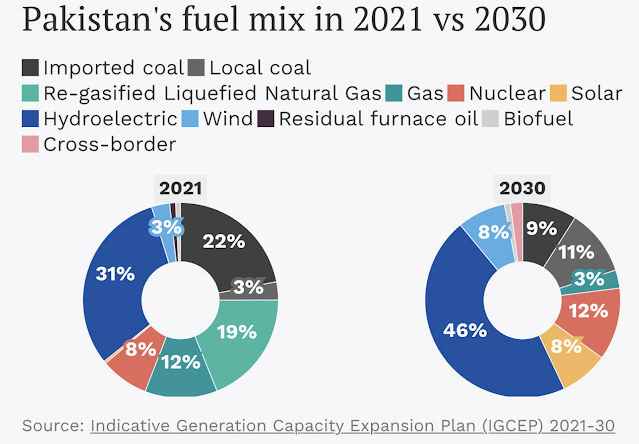

Last year, hydroelectric dams contributed 37,689 GWH of electricity or 27.6% of the total power generated, making hydropower the biggest contributor to power generated in the country. It was followed by coal (20%), LNG (19%) and nuclear (11.4%). Nuclear power plants generated 15,540 GWH of electricity in 2021, a jump of 66% over 2020. Overall, Pakistan's power plants produced 136,572 GWH of power in 2021, an increase of 10.6% over 2020, indicating robust economic recovery amid the COVID19 pandemic.

Lucky power plant in Karachi has been designed to use Thar Lignite Coal when it is available in sufficient quantity. Until that time, it will operate on imported lignite coal. Domestic lignite production is being expanded in a bid to replace costly fossil fuel imports that are depleting Pakistan's foreign exchange reserves and exacerbating circular debt in the power sector, according to Nikkei Asia.

SECMC (Sindh Engro Coal Mining Company) has commissioned a study for converting the China-Pakistan Economic Corridor coal plants in Hub, Jamshoro and Sahiwal to indigenous lignite. A 105km long Thar Rail project is being planned to connect Thar coal fields with Main Line (ML-1) at the New Chhor Halt Station to transport lignite to the power plants in the rest of the country. The transportation of lignite by trucks to Karachi and Kallar Kahar shows its movement by road and rail is feasible and safe despite higher moisture.

|

| Pakistan Electric Power Generation. Source: Arif Habib |

|

| Cost Per Unit of Electricity in Pakistan. Source: Arif Habib |

Construction of 1,100 MW nuclear power reactor K2 unit in Karachi was completed by China National Nuclear Corporation in 2019, according to media reports. Another similar reactor unit K3 is now in operation. It will add another 1,100 MW of nuclear power to the grid in 2022. Chinese Hualong One reactors being installed in Pakistan are based on improved Westinghouse AP1000 design which is far safer than Chernobyl and Fukushima plants.

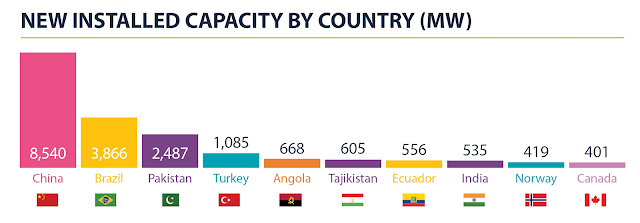

The biggest and most important source of low-carbon energy in Pakistan is its hydroelectric power plants, followed by nuclear power. Pakistan ranked third in the world by adding nearly 2,500 MW of hydropower in 2018, according to Hydropower Status Report 2019. China added the most capacity with the installation of 8,540 megawatts, followed by Brazil (3,866 MW), Pakistan (2,487 MW), Turkey (1,085 MW), Angola (668 MW), Tajikistan (605 MW), Ecuador (556 MW), India (535 MW), Norway (419 MW) and Canada (401 MW).

|

| New Installed Hydroelectric Power Capacity in 2018. Source: Hydrowo... |

Hydropower now makes up about 28% of the total installed capacity of 33,836 MW as of February, 2019. WAPDA reports contributing 25.63 billion units of hydroelectricity to the national grid during the year, “despite the fact that water flows in 2018 remained historically low.” This contribution “greatly helped the country in meeting electricity needs and lowering the electricity tariff for the consumers.”

|

| Pakistan's Current Account Balance vs International Oil Prices. Sou... |

Recent history shows that Pakistan's current account deficits vary with international oil prices. Pakistan's trade deficits balloon with rising imported energy prices. One of the keys to managing external account balances lies in reducing the country's dependence on foreign oil and gas.

|

| Pakistan Power Generation Fuel Mix. Source: Third Pole |

It is true that Pakistan has relied on imported fossil fuels to generate electricity. The cost of these expensive imported fuels like furnace oil mainly used by independent power producers (IPPs) has been and continues to be a major contributor to the "exaggerated external demand driven by its rentier economy" referred to by Atif Mian in a recent tweet. However, Pakistan has recently been adding hydro, nuclear and indigenous coal-fired power plants to gradually reduce dependence on imported fossil fuels.

Related Links:

Haq's Musings

South Asia Investor Review

Pakistan Among World's Largest Food Producers

Food in Pakistan 2nd Cheapest in the World

Indian Economy Grew Just 0.2% Annually in Last Two Years

Pakistan to Become World's 6th Largest Cement Producer by 2030

Has Bangladesh Surged Past India and Pakistan in Per Capita Income?

Pakistan's Computer Services Exports Jump 26% Amid COVID19 Lockdown

Coronavirus, Lives and Livelihoods in Pakistan

Vast Majority of Pakistanis Support Imran Khan's Handling of Covid1...

Pakistani-American Woman Featured in Netflix Documentary "Pandemic"

Incomes of Poorest Pakistanis Growing Faster Than Their Richest Cou...

Can Pakistan Effectively Respond to Coronavirus Outbreak?

How Grim is Pakistan's Social Sector Progress?

Double Digit Growth in Pakistan's Energy Consumption Confirms Econo...

Trump Picks Muslim-American to Lead Vaccine Effort

COVID Lockdown Decimates India's Middle Class

Pakistan to be World's 7th Largest Consumer Market by 2030

Pakistan's Balance of Payments Crisis

How Has India Built Large Forex Reserves Despite Perennial Trade De...

Conspiracy Theories About Pakistan Elections"

PTI Triumphs Over Corrupt Dynastic Political Parties

Strikingly Similar Narratives of Donald Trump and Nawaz Sharif

Nawaz Sharif's Report Card

Riaz Haq's Youtube Channel

-

Comment by Riaz Haq on August 8, 2022 at 10:09am

-

#US wood pellets export booming. #UkraineWar has cut off the supply of compressed-wood pellets from #Russia, #Belarus and #Ukraine to the #power plants in Western #Europe that burn them instead of #coal to reduce #carbon emissions. #energy https://www.wsj.com/articles/wood-pellet-exports-boom-amid-ukraine-... via @WSJ

https://twitter.com/haqsmusings/status/1556688169524899852?s=20&...

The wood-pellet market is on fire.

War has cut off the supply of compressed-wood pellets from Russia, Belarus and Ukraine to the power plants in Western Europe that burn them instead of coal. That has put a premium on pellets from North America, especially the U.S. South.

U.S. export volume, which has climbed steadily over the past decade, is running ahead of last year, when a record of more than 7.4 million metric tons of U.S. wood pellets were sold abroad, according to the Foreign Agricultural Service. The average price before insurance and shipping costs has risen to nearly $170 a metric ton, from around $140 last year.

Prices for on-the-spot deliveries, which can be scarce in a business that runs mostly on long-term supply deals, have jumped to almost twice that, analysts and pellet executives say.

The big winner has been Enviva Inc., EVA 5.69%▲ a Bethesda, Md., company that accounts for the bulk of U.S. wood-pellet exports, and its largest shareholder, New York energy investment firm Riverstone Holdings LLC, AP4 0.00%▲ which has a 42% stake.

Enviva’s shares have returned 114%, including price change and dividends, since just before the pandemic lockdowns, better than twice the S&P 500’s 46% total return over that span.

Enviva is building several new pellet plants in the Southern Pine Belt with the aim of doubling production capacity over the next five years. It buys branches, bark, understory brush, sawdust, spindly or diseased logs and other waste wood from landowners and sawmills and processes the fiber into pellets that are about the circumference of a piece of chalk.

The company’s output flows from ports along the Atlantic and the northern Gulf of Mexico to European utilities and through the Panama Canal to Asia. Japan is a big importer, and Enviva has set up a sales outpost in Taiwan ahead of a big state-owned coal plant’s conversion to pellets.

The company on Thursday said it signed five-, 10- and 15-year supply contracts with new customers in Germany. One will burn Enviva’s pellets to produce heat used in a manufacturing process and another is replacing lignite coal and natural gas, which have surged in price even more than pellets. An existing customer elsewhere in Europe agreed to pay a higher price in exchange for more guaranteed volume.

----------

Analysts say changes in government policies are one of the biggest threats to Enviva and others in the pellet business. The European Parliament’s environmental committee in May voted to stop encouraging the burning of woody biomass by eliminating its eligibility for renewable-power subsidies and changing how emissions are counted, but the full parliament would need to sign on to change the rules.

“Particularly amid the war and resulting natural-gas supply crisis, this seems like the worst possible time to change policy on bioenergy,” Raymond James analysts wrote to clients last week. “We doubt that the committee will get its way, at least anytime soon.”

Enviva’s Mr. Keppler said he doesn’t believe Europe’s demand for pellets will slow, given the alternatives. “Europe used to have a natural-gas transition strategy away from coal,” he said. “Today, it’s nothing but risk.”

-

Comment by Riaz Haq on August 8, 2022 at 8:35pm

-

Pakistan’s Thar desert lignite coal boom gathers pace with SECMC mine hitting 10 Mt & SSRL mine starting up

https://im-mining.com/2021/12/31/pakistans-thar-desert-lignite-coal...

On December 17, 2021, Sindh Engro Coal Mining Company (SECMC) announced that it had successfully achieved the 10 Mt of coal production milestone. SECMC, one of the largest public-private partnerships in the energy sector in Pakistan, commenced commercial operations in July 2019 with an annual production capacity of 3.8 Mt. Over the past 2.5 years, SECMC has begun to transform the energy landscape of Pakistan by facilitating production of electricity using indigenous coal reserves. The coal feeds a 660MW coal fired power plant and the overall project is classed as a is classed as a China-Pakistan Economic Corridor (CPEC) priority implementation project.

SECMC is one of two main lignite coal mining operators in the country, and is located in in Block II of the Tharparkar (Thar) area in Sindh province of Pakistan. It is a joint venture between the Government of Sindh (GoS), Engro Energy Ltd (formerly Engro Powergen Limited) and its partners namely Thal Ltd (House of Habib), Habib Bank Ltd (HBL), Hub Power Company (HUBCO); and China Machinery Engineering Corporation (CMEC). The world class Huolinhe Open Pit Coal Mine in Inner Mongolia, China, a subsidiary of China’s State Power Investment Corporation, has also joined the SECMC board as strategic investor with preference shares’ subscription.

The other main mine in the country which is just going into production is operated by Sino Sindh Resources Ltd (SSRL) which is located in Block I of the same Thar region; it is also a CPEC project and is owned by Chinese group Shanghai Electric Power Company Ltd. It comprises a 7.8 Mt/y open-pit coal mine and installation of a 1,320MW coal-fired power plant (2 x 660MW). Mining work was set to be completed by end 2021 and the first unit of the power plant is due to start working from 2022 while the entire project is scheduled to be completed by 2023. SSRL has a large mining fleet comprised of 55 t MT86D Chinese wide body trucks from LGMG to be loaded by 28 Liebherr R 9100B hydraulic mining excavators, the largest single mine fleet of this model in the world.

The SECMC mine uses a large fleet of 130 Chinese 60 t TONLY TL875 wide body trucks for coal haulage which are loaded by 18 hydraulic excavators, mainly Komatsu PC1250 units. The record production has resulted in the generation of over 10,000 GwHs of electricity, contributing to the national grid. Besides, the company’s record production of coal and generation of electricity using Thar’s local reserves has benefitted the national economy by saving $210 million through import substitution during the same period.

-

Comment by Riaz Haq on August 8, 2022 at 8:35pm

-

Pakistan’s Thar desert lignite coal boom gathers pace with SECMC mine hitting 10 Mt & SSRL mine starting up

https://im-mining.com/2021/12/31/pakistans-thar-desert-lignite-coal...

During the course of operations, SECMC has maintained a good safety record following international and world-class benchmarks – a feat that has earned international acknowledgements from organisations such as the British Safety Council. SECMC has also adopted the United Nation’s Sustainable Development Goals (SDG) framework to deploy high-impact interventions prioritising education, health, economic growth and women empowerment amongst other areas.

SECMC has also contributed to uplifting the local community by generating employment opportunities for the local population and creating other economic avenues for the community. It is pertinent to mention that 80% of the employees in SECMC are locals from Sindh where the project has provided significant socio-economic benefit to the local Thari population.

“The 10 Mt coal production mark is a commendable achievement considering the constant fluctuation and vulnerability in international coal prices,” said Chief Executive Officer SECMC – Amir Iqbal. He added that Thar coal is the best resource to help the national economy in terms of easing out the pressure on the Current Account Deficit and also indigenise the current energy mix which is heavily reliant on imported fuels. Currently, the second phase of the SECMC mine is already under development which will increase SECMC’s production to 7.6 Mt per annum with a cumulative power generation of 1,320MW.

Talking about the subsequent phase III expansion project, Iqbal said that the estimated investment for phase III expansion is to be approximately $100 million which will enable Thar Block-II to achieve a sustainable supply of 12.2 Mt of coal annually over the next 30 years. SECMC is expected to complete this expansion by June 2023 and with this expansion coal price of SECMC mine is to be reduced to under $30/t – making it the cheapest fuel source in the country ensuring economic stability and energy security for the country. In addition, phase III expansion will also enable Pakistan to save $420 million per annum on the account of import substitution whilst also leading to a reduction of PKR74 billion in circular debt on an annual basis.

-

Comment by Riaz Haq on August 12, 2022 at 11:13am

-

In the fiscal year 2019-2020, four coal-fired CPEC power plants generated 19 percent of Pakistan’s electricity. The 4.62 GW of coal-fired generation funded by CPEC includes the 1,320 MW Huaneng Shandong Ruyi-Sahiwal Coal Power Plant, the 1,320 MW Port Qasim Coal Fired Power Plant, the 1,320 MW HubCo Coal Fired Power Plant, and the 660 MW Engro Thar Coal Power Plant, all of which began supplying electricity to the national grid between 2017 and 2019. Construction on the Thal Nova, Thar Energy (HubCo), and Shanghai Electric (SSRL Thar Coal Block I) power plants to increase 1,980 MW of capacity is currently underway.

https://tribune.com.pk/story/2369846/is-there-a-solution-to-pakista...

-

Comment by Riaz Haq on August 15, 2022 at 4:09pm

-

No light matters

By Engr. Hussain Ahmad Siddiqui Mon, 08, 22

In a major development, the government plans to use indigenous Thar coal, instead of imported coal, for generation of 3,960MW.

https://www.thenews.com.pk/magazine/money-matters/982273-no-light-m...

The three power plants that would be shifted to indigenous coal are Sahiwal Coal Power (Sahiwal), China Hub Coal Power (Hub) and Port Qasim Coal (Port Qasim, Karachi), each of 1,320MW installed capacity. It is indeed a landmark and timely decision since when implemented it would reduce reliance on costly imported coal, and bring down electricity rates, resulting in energy security and overall economic development.

Various measures have already been taken by the government in this direction. Consultants have been appointed to work out feasibility of substitution of existing import-based fuel mix to Thar coal. These power plants would require conversion of existing plant machinery partially, involving lead-time and additional capital cost for the conversion, since coal-based power plants are custom-designed and technology selected depends on coal analysis and characteristics. Also, the government will develop Thar Rail Project, a 105km long rail link for bulk transportation of coal from Thar coalfields to various power-plant destinations through main railway line at the New Chhor station. The project (track and rolling stock) will be established on BOT basis.

Thar lignite (brown coal) is suitable for thermal power generation, and a series of integrated mine-mouth power projects are being established. Two power plants of cumulative capacity of 990MW are operational. The pioneering project Engro Powergen Thar Coal of 660MW (2x330MW) installed capacity, is successfully generating billions of units (kWh) of low-cost electricity on an annual basis since July 2019, whereas Thar Energy Ltd (Hubco) of 330MW has been commissioned this month and will achieve commercial operations soon. Both power plants, which are connected to the national grid, are part of the China-Pakistan Economic Corridor (CPEC) energy programme.

---------

At present, understanding about the nature of Thar coal is limited insofar as its physical properties, chemical analysis, and behaviour are considered. Thar coal, which is classified as lignite-B and subbituminous-A (ASTM classification) having heating value in the range of 6,244-11,054 BTU/lb, is suitable for power generation. Lignite of similar character and quality is being used for power generation on commercial scale in India, Germany, Hungary and Serbia. Its chemical composition and heating values vary from block to block, which have not been largely tested in use. Coal at Block-II has moisture 48.80 percent, ash 5.21 percent, sulphur 1.05 percent, fixed carbon 19.37 percent, and volatile matter 25.57 percent, having heating value 5,780 BTU/lb. High moisture is a major contributor restricting its transportation to long distances due to a variety of problems and risks.

-

Comment by Riaz Haq on August 15, 2022 at 6:48pm

-

Lignite Combustion

https://www3.epa.gov/ttnchie1/old/ap42/ch01/s07/final/c01s07_oct199...

Lignite is a coal in the early stages of coalification, with properties intermediate to those of

bituminous coal and peat. The two geographical areas of the U. S. with extensive lignite deposits are

centered in the States of North Dakota and Texas. The lignite in both areas has a high moisture

content (20 to 40 weight percent) and a low heating value (5,000 to 7,500 British thermal units per

pound [Btu/lb], on a wet basis). Due to high moisture content and low Btu value, shipping the lignite

would not be feasible; consequently, lignite is burned near where it is mined. A small amount is used

in industrial and domestic situations, but lignite is mainly used for steam/electric production in power

plants. Lignite combustion has advanced from small stokers to large pulverized coal (PC) and

cyclone-fired units (greater than 500 megawatt).

The major advantages of firing lignite are that it is relatively abundant (in the North Dakota

and Texas regions), relatively low in cost since it is surface mined, and low in sulfur content which

can reduce the need for postcombustion sulfur emission control devices. The disadvantages are that

more fuel and larger, more capital-intensive facilities are necessary to generate a unit of power with

lignite than is the case with bituminous coal. The disadvantages arise because: (1) lignite’s lower

heating value means more fuel must be handled to produce a given amount of power; (2) the energy

and maintenance costs of coal handling equipment are higher; (3) the high inherent moisture content of

lignite decreases boiler efficiency; and (4) the ash characteristics of lignite require more attention to

sootblowing and boiler operation to maintain high availability and reliability

In a pulverized lignite-fired boiler, the fuel is fed from the stock pile into bunkers adjacent to

the boiler. From there, the fuel is metered into several pulverizers which grind it to approximately

200-mesh particle size. A stream of hot air from the air preheater begins the fuel-drying process and

conveys the fuel pneumatically to the burner nozzle where it is injected into the burner zone of the

boiler. Firing configurations of boilers that fire pulverized lignite include tangential, horizontally

opposed, front wall, cyclone, stoker, and fluidized bed combustor.

In the tangential firing method, the pulverized lignite is introduced from the corners of the

boiler in vertical rows of burner nozzles. Such a firing mechanism produces a vortexing flame pattern

which essentially uses the entire furnace enclosure as a burner. In front-wall firing and horizontally

opposed firing boilers, the pulverized coal is introduced into the burner zone through a horizontal row

of burners. This type of firing mechanism produces a more intense combustion pattern than the

tangential design and has a slightly higher heat release rate in the burner zone itself.

-

Comment by Riaz Haq on August 21, 2022 at 4:15pm

-

The last stator frame at the (864 MW) Suki Kinari hydropower project (on the Kunhar river in the Kaghan valley of Mansehra District Khyber Pakhtunkhwa) has been hoisted successfully and lowered into the unit pit.

https://www.app.com.pk/global/last-stator-hoisted-successfully-at-c...

The stator weighed 335 tons and the task was completed with the help of bridge cranes. The project has four electricity generation units with a combined capacity of 884 megawatts.The run-of-river facility is one of the early-harvest clean energy projects under China-Pakistan Economic Corridor (CPEC). Gezhouba Group, China is implementing the project at around $2 billion, China Economic Net (CEN) reported.

Also, the 5-kilometre-long relocated portion of National Highway 15 (N-15) is open to traffic. The existing portion of N-15 will submerge in the reservoir of the Suki Kinari hydropower project; therefore, the new road was constructed at a higher elevation. The new road also has a 411-metre-long tunnel.

The project is expected to complete by the end of 2023 or mid 2024, an official said. He said that the powerhouse and reservoir parts of the project were at advanced stages of completion. However, the 24-kilometre-long headrace tunnel is the most challenging part of the project due to unpredictable terrain, tough weather conditions during winters and dewatering issues, he said.

Gezhouba has deployed the most skilled workforce and state-of-the-art machinery at the tunnel sites and presently excavation and lining works are underway from both upstream and downstream sides, he said.

The project will add around 3 billion units of cheap electricity into the national grid annually after completion.

-

Comment by Riaz Haq on August 24, 2022 at 11:06am

-

Steve Hanke

@steve_hanke

With winter looming, Germany’s central planners have a new strategy for importing energy: prioritize coal shipments by rail. Passengers be damned. Ill-advised sanctions on Russia & an incompetent Scholz government are proving to be a deadly German cocktail.

https://twitter.com/steve_hanke/status/1562439587473096704?s=20&...

--------

Germany To Prioritize Coal Shipments Across Rail Network Over Passenger Trains Amid Worsening Energy Crisis | ZeroHedge

https://www.zerohedge.com/commodities/germany-set-prioritize-coal-s...

The latest sign lawmakers in Europe's industrial heartland are preparing for what could be a disastrous winter of reduced natural gas supplies from Russia and record high electricity prices is a new proposal to prioritize Germany's rail network for coal shipments over passenger services, according to Bloomberg, citing local newspaper Welt am Sonntag.

Even though Germany has promised to eliminate coal-fired power generation in the coming years, the historic energy crisis has made it more dependent on coal than ever as Russian flows of NatGas slump ahead of winter.

Economy Minister Robert Habeck recently said increased reliance on coal is bitter but necessary.

And we must give our readers a spoiler alert: there's no way Germany will eliminate coal as a power source by 2030. If anything, it will be more reliant on it than ever unless it extends the life of its nuclear power plants.

"Priority is normally given to passenger transport in Germany, and timetables are geared toward it. As a result, there's a risk of chaos on the rails from making the change," Bloomberg said, citing the draft.

-

Comment by Riaz Haq on August 24, 2022 at 11:28am

-

Answering Pakistan’s Burning Question: How To Ignite Lignite?

Amy KoverBuried 1,000 feet below the parched Thar Desert in Pakistan lies more fuel energy than all the known oil in Iran and Saudi Arabia combined. Just a small fraction of this 175-billion-ton lignite coal reserve is plentiful enough to supply one-fifth of Pakistan’s current energy levels for 50 years. This would significantly bolster the energy supply to Pakistan’s 200 million residents, who per capita have access to roughly just 3 percent of the electricity a typical American consumes. As a local resource, it would also lower hefty bills for imported oil and coal, diminishing Pakistan’s reliance on outside sources for energy.

The problem is that lignite is about as combustible as soggy logs in a fireplace. Composed of more than 50 percent water, as well as other impurities, lignite is known as low-caloric fuel — an ideal description for diet products, but not so much for an electricity resource. That’s partly why Thar’s reserve has gone largely untapped since its accidental discovery in 1992 by geologists searching for drinkable water. Even nine years ago, when the private-public partnership Sindh Engro Coal Mining Company purchased 1 percent of the reserve for mining, one question continued to confound power plant operators: How to ignite lignite?

Last month, an answer arrived. GE Power — which has experience burning a similar form of lignite coal in Europe and the U.S. — will bring its boiler and steam turbine technology to Pakistan. Chinese contractor SEPCOIII announced plans, in June, to use GE Power’s systems as part of its new power plant near Karachi. Known as “Qasim-Lucky,” the plant will generate 660 megawatts of electricity to power 1.3 million Pakistani homes and businesses when Lucky Power begins commercial operations in 2021. “As the first lignite-fueled ultra-supercritical power plant across the Middle East, North Africa and Turkey region, the project will help to set new industry benchmarks in Pakistan,” Qin Xubao, project director at SEPCOIII, said recently.

“Ultra-supercritical (USC)” is the operative term here — it describes the titanic pressures GE achieves inside the steam turbine — but first some background. This groundbreaking process begins with GE Power’s mill, known as the Beater Wheel, grinding lignite coal so it’s as fine as baby powder. With more surface area exposed, the tiny particles of coal dry more easily as hot air blows the dust into the combustion chamber. There, even hotter air — temperatures averaging 650 degrees Fahrenheit (340 degrees Celsius) — combusts the pulverized lignite into flue gas.

An “ultra supercritical” steam turbine at the RDK8 power plant in Germany. The water pressure inside reaches 4,000 pounds per square inch, more than what’s exerted when a bullet strikes a solid object. The water, which exists in a “supercritical state,” is heated to 1,112 degrees Fahrenheit (600 degrees Celsius). Top: The boilers of an ultra-supercritical power plant in Neurath, Germany. Images credit: GE Steam Power.

When it comes to combusting lignite, size matters. Every square centimeter of the boiler must fill evenly with gas. Since different fuels burn at different temperatures, GE designs its boilers with Goldilocks dimensions: neither so small that the fuel overheats nor so big that it won’t combust. Just as crucial is the positioning of each component in the boiler. “The way you inject the air into the flame, the way you manage the size of the flame and positioning of the flame, it all impacts how the lignite will react and burn,” explains Sacha Parneix, commercial general manager for GE’s Steam Power business in the Middle East, North Africa and Turkey (MENAT). “We have a lot of design features to make sure that we manage to truly burn this fuel that does not want to completely burn easily.”

Flue gas then travels up to the steam boiler, where its heat transforms water stored in tubes into steam power. The steam’s mechanical energy spins enormous turbines to power electricity generators. It’s also when another kind of engineering magic — GE Power’s steam turbine — kicks in. GE’s ultra-supercritical science puts steam under pressure of roughly 4,000 pounds per square inch — the same impact as a bullet striking a solid object — and heats to 1,112 degrees Fahrenheit (600 degrees Celsius). The heat and pressure turn steam into a supercritical fluid, a phenomenon where a substance no longer has specific liquid and gas phases but exhibits properties of both at the same time. In this state, the steam can get turbines spinning faster than any other system in operation, more than 20 percent above the world-average net thermal-efficiency rate of coal-fired power plants — a measure of how well the plant converts fuel into heat. That kind of efficiency gobbles up less fuel, reducing both operating expenses and carbon dioxide emissions per kilowatt-hour generated.

Though Lucky Power plans to rely on lignite mined from Thar (with some exports for backup), the plant itself is situated 276 miles (445 kilometers) away in the outskirts of densely populated Karachi. That’s a significant boon to Qasim. “On top of being designed for local Pakistani Thar coal, the project’s location ensures easy connectivity to the national grid and very low transmission and distribution losses in supplying affordable power to the major load center of the city of Karachi,” Parneix says.

All of this further augments GE Power’s work to help Pakistan diversify its power grid. Last May, the company achieved commercial operation for two HA gas turbines for the Bhikki combined-cycle plant in Lahore to power up to 2.4 million homes. GE’s HA gas turbines are planned for operation at two other power plants in Pakistan: Balloki, near Chunian, and Haveli Bahadur Shah, in Jhang. The Haveli Bahadur Shah plant alone is expected to add the electricity capacity needed for another 2.5 million homes. GE also worked with Hawa Energy to launch a 50-megawatt wind farm along the Gharo-Keti Bandar wind corridor in Jhimpir. So far, a quarter of Pakistan’s electricity flows through fuel-agnostic GE-built technologies, supporting Pakistan’s fuel-diversification power-generation strategy.

If things go as planned at Qasim, Thar-mined lignite will get to play a starring role in this story of “How Pakistan Got Its Electric Groove On.”

-

Comment by Riaz Haq on August 27, 2022 at 12:01pm

-

The National Transmission and Dispatch Company (NTDC) connected the fourth 330MWs mine-mouth power plant built under China-Pakistan Economic Corridor (CPEC) initiative at Thar coal Block II with the national grid.

https://pakobserver.net/ntdc-connects-330mws-thal-nova-plant-with-n...

“We successfully provided back feed supply/seller’s interconnection facility for Thal Nova power plant through 500kV Thal Nova-Matiari transmission line,” NTDC said according to a report published by Gwadar Pro on Friday. The back feed supply energized the power plant for testing its electrical equipment, the statement added. After completion of the testing, the power plant will start contributing cheaper electricity to the national grid, NTDC said.

Twitter Feed

Live Traffic Feed

Sponsored Links

South Asia Investor Review

Investor Information Blog

Haq's Musings

Riaz Haq's Current Affairs Blog

Please Bookmark This Page!

Blog Posts

Barrick Gold CEO "Super-Excited" About Reko Diq Copper-Gold Mine Development in Pakistan

Barrick Gold CEO Mark Bristow says he’s “super excited” about the company’s Reko Diq copper-gold development in Pakistan. Speaking about the Pakistani mining project at a conference in the US State of Colorado, the South Africa-born Bristow said “This is like the early days in Chile, the Escondida discoveries and so on”, according to Mining.com, a leading industry publication. "It has enormous…

ContinuePosted by Riaz Haq on November 19, 2024 at 9:00am

What Can Pakistan Do to Cut Toxic Smog in Lahore?

Citizens of Lahore have been choking from dangerous levels of toxic smog for weeks now. Schools have been closed and outdoor activities, including travel and transport, severely curtailed to reduce the burden on the healthcare system. Although toxic levels of smog have been happening at this time of the year for more than a decade, this year appears to be particularly bad with hundreds of people hospitalized to treat breathing problems. Millions of Lahoris have seen their city's air quality…

ContinuePosted by Riaz Haq on November 14, 2024 at 10:30am — 2 Comments

© 2024 Created by Riaz Haq.

Powered by

![]()

You need to be a member of PakAlumni Worldwide: The Global Social Network to add comments!

Join PakAlumni Worldwide: The Global Social Network