PakAlumni Worldwide: The Global Social Network

The Global Social Network

Pakistan Garment Industry Becoming More Cost Competitive With Bangladesh's?

Low wages and trade preferential deals with Western nations have helped Bangladesh, currently designated "Least Developed Country" (LDC), build a $30 billion ready-made garments (RMG) industry that accounts for 80% of country's exports. Bangladesh is the world's second largest RMG exporter after China. With its designation as LDC (Least Developed Country), garments made in Bangladesh get preferential duty-free access to Europe and America. Rising monthly wages of Bangladesh garment worker in terms of US dollars are now catching up with the minimum wage in Pakistan, especially after recent Pakistani rupee devaluation. Minimum monthly wage in Pakistan has declined from $136 last year to $107 now while Bangladesh has seen it increase from $64 last year to $95 today. Western garment buyers, known for their relentless pursuit of the lowest labor costs, will likely diversify their sources by directing new investments to Pakistan and other nations. Competing on low cost alone may prove to be a poor long term exports strategy for both countries. Greater value addition with diverse products and services will be necessary to remain competitive as wages rise in both countries.

|

| Minimum Monthly Wages in US$ Market Exchange Rate |

Wage Hike in Bangladesh:

The government in Dhaka announced in September that the minimum wage for garment workers would increase by up to 51% this year to 8,000 taka ($95) a month, up from $64 a year ago, according to Renaissance Capital. But garment workers union leaders say that increase will benefit only a small percentage of workers in the sector, which employs 4 million in the country of 165 million people, according to Reuters. Bangladesh government promised this week it would consider demands for an increase in the minimum wage, after clashes between police and protesters killed one worker and wounded dozens.

| Monthly Minimum Wages in US$. Source: Renaissance Capital |

Pakistan Wage Decline:

Pakistani currency has seen about 25% decline in value against the US dollar since January 2018. As a result of this devaluation, the minimum monthly wage in Pakistan has dropped from $136 last year to $107 now while Bangladesh has seen it increase from $64 last year to $95 today. Renaissance Capital projects a further 10% depreciation in Pakistani rupee this year.

Race to the Bottom?

Competing on cost alone is like engaging in the race to the bottom. Neither Pakistan nor Bangladesh can count on being lowest cost producers in the long run. What must they do to grow their exports in the future? The only viable option for both is to diversify their products and services and add greater value to justify higher prices.

Pakistan's Export Performance:

|

|

|

|

| Top 10 Textile Exporters. Source: WTO |

|

| Top 10 Garment Exporters. Source: WTO |

Pakistan's Role:

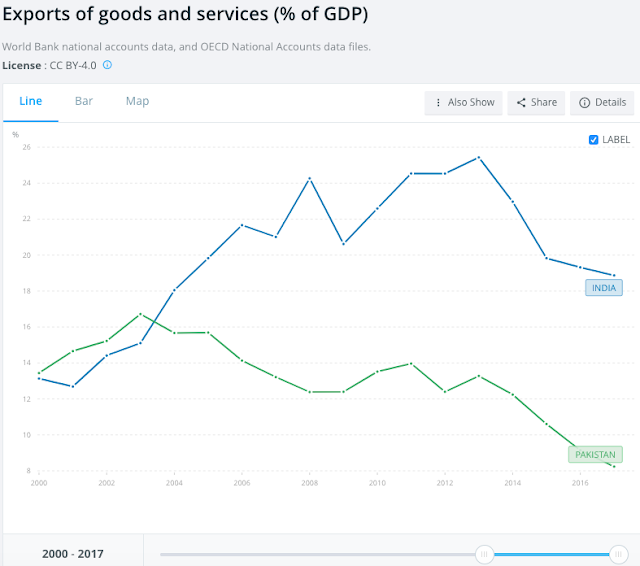

Pakistani currency has seen about 25% decline in value against the US dollar since January 2018. As a result of this devaluation, the minimum monthly wage in Pakistan has dropped from $136 last year to $107 now while in Bangladesh has seen it increased from $64 last year to $95 today. Renaissance Capital projects a further 10% depreciation this year. While this can help Pakistan's RMG exports in the short term, it is not good long term strategy. Competing on cost alone is a race to the bottom. Pakistan's manufactured exports per capita have declined in the last decade. Pakistan's exports have declined from about 15% of GDP to about 8% since 2003. The nation's trade deficits are growing at an alarming rate as the imports continue to far outstrip exports. This situation is not sustainable. Chinese Ambassador Yao Jing has offered a helping hand to increase Chinese investment and trade in Pakistan. Pakistan's new government led by Prime Minister Imran Khan should take the Chinese Ambassador's plan seriously. Finance Minister Asad Umar needs to form a high-powered team of top bureaucrats and leading businessmen on a comprehensive plan to attract investments in export-oriented industries and diversify and grow high-value exports to China and other countries.

-

Comment by Riaz Haq on June 7, 2020 at 4:40pm

-

#Pakistan, #China universities sign agreement on #textile cooperation between National Textile University (NTU) Pakistan and #Shanghai University of Engineering Science (SUES) of China| Associated Press Of Pakistan

An agreement on textile cooperation was jointly signed by National Textile University (NTU), Pakistan and Shanghai University of Engineering Science (SUES), China last week.

According to SUES, NTU is the very first Pakistani partner for SUES, and the move is of great significance when it comes to the educational exchanges and cooperation between universities of South Asian countries involved into China’s Belt and Road Initiative (BRI), China Economic Net reported on Friday.

Xia Jianguo, the President of SUES, noted that the signing ceremony was SUES’s first move of international cooperation ever since the COVID-19 outbreak. The iron-clad friendship between China and Pakistan has laid a solid foundation for the cooperation and exchanges between both universities.

President Xia spoke highly of the competences and characteristics of research and talent training in NTU regarding textile. Over the years, SUES has conducted a wide range of international exchanges and cooperation with overseas universities and enterprises, he mentioned, adding that he firmly believed the cooperation would provide both with more opportunities for common development.

Prof Dr. Tanveer Hussain, the Rector of NTU, expressed his heartfelt thanks to SUES for the arrangement and preparation for the video signing ceremony.

He said NTU has been the premier institute of textile education in Pakistan, meeting the technical and managerial human resource needs of almost the entire textile industry of Pakistan ever since its inception.

What is more, he expressed full confidence and keen expectation for a long-term cooperation between the two universities in multiple levels and fields.

The signing ceremony was held in video form. Directors from SUES’s Office of International Cooperation and Exchange and the Institute of Textile and Garment were present.

-

Comment by Riaz Haq on July 8, 2020 at 9:10pm

-

#German international brand Hugo Boss places first order for sportswear with a #Pakistani #garment manufacturing company. #exports #RMG

https://nation.com.pk/08-Jul-2020/hugo-boss-places-first-order-of-s...

Adviser to the Prime Minister on Commerce and Investment Abdul Razak Dawood on Tuesday said that well known brand, Hugo Boss has placed its first order of sportswear to a Pakistani company. “Happy to note that well known brand, Hugo Boss, has placed its first order of sportswear to a Pakistani company,” the Adviser said on Twitter. He attributed this achievement due to the effort of Pakistan Readymade Garments Manufacturing and Exporters Association (PRGMEA) for holding the 35th IAF Fashion Convention in November last year, in Lahore.

The International Apparel Federation’s (IAF) 35th World Fashion Convention was held in Lahore on November 12-13, 2019, in collaboration with Dutch industry association Modint.

German fashion house Hugo Boss is known around the world for its smart men’s suits. It manufactures clothing and accessories internationally and has various products, such as eveningwear, shoes, leather goods, eyewear, watches, perfumes, and children’s fashion. It recently launched more casual and sportswear styles in order to attract younger people, making major investments in online products after its attempt to go upmarket failed some years ago.

In another Tweet, the Adviser said that Pakistan’s exports had reduced less as compared to other countries of the region due to the Covid-19 pandemic. He said that Pakistan’s exporters had performed well in last fiscal year despite slowdown in economic activities due to the Covid-19.

“I want to congratulate all our exporters on the good performance in 2019-20, in spite of the very challenging situation caused by Covid,” he said and added that Pakistan’s exports were only 6 percent less than 2018-19, while our regional countries Bangladesh was down 17 percent and India down by 14 percent.

This good performance was also due to the timely lifting of the lockdown and the good coordination between federal and provincial agencies at the daily meetings of NCOC. Our exporters deserver every praise for their effort, hard work and reaching out to our customers, he added.

-

Comment by Riaz Haq on July 9, 2020 at 7:29am

-

#Pakistan Denim Manufacturers Are Cautiously Optimistic About Recovery. Pak denim industry experiencing “a surge of orders,” due to “pent-up demand for garments, particularly from Europe.” #exports #garment #jeans #denim https://sourcingjournal.com/denim/denim-mills/lenzing-pakistan-manu... via @SourcingJournal

Most industries in every country have been adversely effected by the coronavirus. In Pakistan, however, the textile industry is among the hardest-hit sectors.

“Pakistan textile industry is a key exporter for the country accounting for more than half of all overseas shipments,” said Tricia Carey, Lenzing’s director of global business development-denim.

In a recent Carved in Blue webinar, Carey moderated a conversation with representatives from denim fabric and garment manufacturers in Pakistan, checking in on the status of their business and how they plan to navigate the challenges that lie ahead.

With more than 200,000 confirmed cases of the coronavirus, the country remains on a “smart lockdown” that requires shopping malls and restaurants to be closed, but essential businesses and export industries have received permission to operate under strict guidelines, explained Hasan Javed, director of Artistic Garment Industries (AGI).

AGI resumed business slowly at the end of April. Initially, Javed said, the main focus was to implement training and awareness sessions held in small groups at the facility about how to conduct work safely under the new guidelines.

“It took some time for everyone to get used to the social distancing rules and the ‘new normal’ as they say,” he said. “Now in the last few months we have gradually ramped up our production, and at the moment we’re running close to 80 percent [capacity].”

The goal for July, Javed added, is to run at close to full strength, both on the fabric and garment side of AGI’s business. “We’re fairly optimistic about the next couple of months,” he said.

Business in Pakistan has improved since April when the country was in a total shutdown, said Rashid Iqbal, Naveena Denim Lahore (NDL) executive director. NDL’s production is running at 40-50 percent capacity and Iqbal expects those numbers to hold steady for July.

Momentum is also building for Azgard Nine Ltd. Ahmed Humayun Shaikh, CEO of Azgard Nine Ltd., said the company is experiencing “a surge of orders,” which he attributes to “pent-up demand for garments, particularly from Europe.”

But he warned that this flurry of orders is fleeting. “I don’t think we can expect the pandemic to actually increase demand so it will settle down at some reduced rate once people get what they need,” Shaikh said.

When markets do finally resume at a normal level, executives anticipate that Pakistan will regain its share and perhaps be in better standing in the global denim market.

“The reason being, when it comes to the supply chain Pakistan is the fifth-largest cotton growing country in the world with a fabric capacity of 500 million meters a year,” Iqbal said. “We’re very ideally placed.”

To fully realize this this opportunity, Iqbal said agility is going to be the “name of the game.”

However, in order to be agile, companies may want to eliminate the number of suppliers essential to production.

As brands recover, Crescent Bahuman Ltd. representative Zaki Saleemi said companies will want to simplify their suppliers and inventories, which may bode well for Pakistan’s crop of vertical denim manufactures.

“We are a lot more vertical than a lot of other countries,” he said. “Vertical is key.”

Shaikh agreed, adding that customers want goods quickly because “they’re nervous and they want to fill the shelves.”

-

Comment by Riaz Haq on September 22, 2020 at 1:40pm

-

Readymade Garments Exports Increase By 18.04%

https://www.urdupoint.com/en/business/readymade-garments-exports-in...

The Readymade Garments exports during first month of current financial year increased by 18.04 percent as compared the corresponding period of the last year.

According to Pakistan Bureau of Statistics (PBS), the Readymade garments exports worth US $274,246 thousand in first month of current financial year to US $232,327 thousand of the same period of last financial year.

During the period from July 2020, exports of Art, Silk and Synthetic textile increased by 14.

01%, worth $28,388 thousand as compared the exports valuing $24,900 thousand of same period of last year, it added.

Meanwhile, Madeup Articles exports increased by 26.04%, worth $60,805 thousand as compared the exports of valuing $48,244 thousand of the corresponding period of last year.

During the period under review, buses, Other Textile materials exports increaseed by 66.46%, valuing $48,758 thousand exported as compared the export worth $29,292 thousand of same period of last year.

----------

Garment orders move to Pakistan, as COVID bites India, Bangladesh

However, the garment sector in the country is facing a severe shortage of yarn due to a shortage of cotton.

https://www.brecorder.com/news/40020319

As the coronavirus pandemic continues to spread unabated in India and Bangladesh, garment orders from international markets are rapidly shifting towards Pakistan.

However, the garment sector in the country is facing a severe shortage of yarn due to a shortage of cotton.

As per reports, the development comes at a time when export orders are declining in Pakistan's neighboring countries due to the COVID pandemic, there is a flurry of export orders for Pakistan's garment sector, as India and Bangladesh, affected by the pandemic, have not yet been able to produce and deliver goods to European and American markets on time.

This has pushed the entire production pressure of the textile industry on Pakistan's textile exports.

However, there exist a major hurdle for the local industrialists to take advantage of this opportunity, as they say, that they are worried about the shortage of raw material, especially yarn, for the orders received by the garment sector.

Industrialists say that the international client gives 35 to 40 days for shipments but the local mill is giving them three months' time.

Exporters say that if the government does not take immediate action, not only will orders from rival countries stop moving to Pakistan, but local industrialists will also lose out to permanent buyers.

-

Comment by Riaz Haq on December 6, 2020 at 7:14am

-

#Faisalabad headquartered apparel giant Interloop has begun to divest from #Bangladesh and invest in #Pakistan

https://profit.pakistantoday.com.pk/2020/11/28/interloop-divests-fr...

Why is it that if one looks at the tags of clothes bought in Europe, they will invariably say ‘Made in Bangladesh’? Entirely European fast fashion brands like Zara (which is a Spanish retailer) will manufacture their clothes in Bangladesh.

There is a specific reason for this, and not just the usual developing world cliches of ‘cheap labour’ and ‘advantage in cotton’. Technically speaking, Bangladesh has been part of the World Trade Organisation since 1995. But in 2001, it would make a decision that would alter its fortunes for the better. That year, the country signed the ‘EU-Bangladesh Cooperation Agreement’ with the European Union. That agreement provides broad scope for cooperation, extending to trade and economic development, human rights, good governance and the environment.

But the real benefit, of course, was trade. Bangladesh was to receive duty-free access to EU markets under a programme known as the globalised scheme of preferences (GSP), designed to help developing countries grow through trade. The country has the most generous level of GSP, aimed at least-developed countries.

And it worked. For instance, in 2015, the EU accounted for 24% of Bangladesh’s total trade. Over 90% of the EU’s total imports from Bangladesh were in clothing. More impressively, between 2008 and 2015, EU imports from Bangladesh trebled from €5,464 million to €15,145 million, which represented nearly half of Bangladesh’s total exports.

One textile company in Pakistan took notice: the sock moguls, Interloop. The company is one of Pakistan’s fastest-growing and most exciting textile companies, and let us explain why.

-

Comment by Riaz Haq on December 6, 2020 at 7:14am

-

Analyst Briefing: Interloop To Continue To Operate At Full Capacity Due To Healthy Order Books

https://www.mg-link.net/news/38143/Analyst-Briefing-Interloop-to-co...

The Company also decided to divest its investment from Interloop Bangladesh soon due to non-cooperative attitude of Bangladesh govt by not issuing visas to investors.

---------------

To recall, the company reported 2.7x YoY increase in net profits after tax for 1QFY21 to Rs 1.33 billion (EPS: Rs1.53), compared to Rs 491 million (EPS: Rs 0.56) in the same period last year.

The management informed that company earned profits on the back of higher net sales which increased by 38% YoY during 1QFY21 to Rs 13 billion primarily due to hosiery utilization at 100% post revival of economic activity, increase in utilization of the denim plant given addition of new customers, and addition of new machineries in its hosiery division.

The key points of the briefing covered by Arif Habib Limited revealed that the company is currently operating at full capacity in both the Hosiery and Denim segments, and it will continue this utilization level for the entire year as it has enough orders from customers.

The company’s Denim segment, which became operational in December 2019, had been impacted significantly by the pandemic. However, the management expects it to become profitable from April 2021, as the company has been adding more reputable customers, such as Guess and Mustang jeans into their portfolio.

Discussing about company’s business diversification and expansion plan, management informed that Interloop entered into the Denim Apparel Segment and successfully installed a production facility with a capacity of 20,000 pieces per day. The First phase has successfully started operations in 2QFY20. Unfortunately, the COVID-19 pandemic affected the business badly as it faced cancellation of orders, as result, during the 1QFY21, Denim Plant operated at around 57% utilization.

In the second phase of the Denim plant which will become operational in last quarter of FY21, the production capacity will be enhanced to 40,000 pieces per day, the management said, adding that the project is 97% complete in terms of infrastructure and utilities. The project cost is around Rs 8.3 billion out of which 81% of the budget has already been consumed. Upon completion both denim and hosiery plant are expected to generate more sales, and profits because of economies of scale. The exports of the company would increase to US$400-450mn when all the announced expansion projects will be completed (exports are currently US$209mn), the management highlighted.

Shedding light on the furture prospects of the company, the management is of the view that their future prospects are encouraging because export orders for ILP are expected to remain robust due to the strong order flows received from the customers. So far, the company has not seen any impact of second wave of Covid-19, as ILP has not witnessed any order cancellations due to onine sales delivey, the added.

The management also disclosed that the company has signed an agreement with Organic Cotton Accelerator to develop the local organic cotton supply chain. Pakistan used to import organic cotton from India; however, due to political issues between the two countries, Pakistan is importing organic cotton from other countries, like Turkey, Africa, which is quite expensive. Moreover, due to the shift of brands toward organic cotton, there is a need to grow organic cotton locally.

With regards to the Apparels segment (IL Apparel), the management underlined that the company is receiving positive responses for their products (knitwear). Currently, the segment only consists of cutting and sewing divisions, where the company procures fabric from external suppliers. The company also plans on expanding the segment in order to add knitting and dyeing units, in the future, which could add further value to the business, the management disclosed.

-

Comment by Riaz Haq on December 6, 2020 at 7:32am

-

Sheikh Hasina Welcomes #Pakistani Envoy to Residence in Yet Another Sign of Thaw in Frosty Relations. #Bangladesh cannot forget the "atrocities" committed by Pakistan during the 1971 war but she ‘s positive about regional cooperation. #India #China #Modi

https://thewire.in/south-asia/pakista-bangladesh-ties-sheikh-hasina...

In yet another signal that the frosty relations between Dhaka and Islamabad could be thawing, Bangladeshi Prime Minister Sheikh Hasina welcomed Pakistan high commissioner Imran Ahmed Siddiqui to her official residence on Thursday.

Though a press release issued by her office quoted Hasina as saying that her country cannot forget the “atrocities” committed by Pakistan during the 1971 war, she was also positive about regional cooperation and smoothening out diplomatic relations.

The two South Asian countries have traditionally not shared close diplomatic relations. The relationship took a “nosedive” during Hasina’s second tenure as prime minister in 2009, when she began focusing on trials for war crimes during the 1971 war which saw the formation of Bangladesh.

In 2016, Bangladesh executed several leaders of the Jamaat-e-Islami party on charges of committing war crimes in 1971. This led to ties with Islamabad falling to a new low, with Pakistan describing the executions and trials “politically motivated”.

On Thursday, Hasins extended greetings to her counterpart Imran Khan after high commissioner Siddiqui conveyed the “good wishes” of the Pakistani PM. The high commissioner said Khan had advised his representatives in Dhaka to learn about the “development miracle” of Bangladesh.

Siddiqui also raised the issue of different bilateral and regional forums remaining inactive, according to reports, and sought Hasina’s help to activate foreign office consultations between the two countries. Hasina said there is no bar from her government to continue functioning regularly.

The high commissioner also said that Pakistan wants to boost relations with Bangladesh without any obstruction, which Hasina said was in line with her government’s foreign policy of “friendship to all malice to none.”

The appointment of Siddiqui as high commissioner in February this year has been crucial in improving the relations between the two nations. In July, after months of ‘quiet diplomacy’ Khan and Hasina had a 20-minute phone conversation which was described as ‘diplomatic coup’ for Islamabad by The Telegraph.

“The new Pakistani high commissioner in Dhaka too has been trying to connect the two Prime Ministers, and finally it happened,” a source in Dhaka told the newspaper.

-

Comment by Riaz Haq on December 25, 2020 at 12:22pm

-

This year, after Pakistan lifted its comprehensive coronavirus lockdown in May while other countries in the neighborhood kept their economies closed, international textile orders have been diverted to Pakistan, leading to a nine-year record in exports, Aliya Hamza Malik, parliamentary secretary for commerce, told Arab News.

https://www.arabnews.pk/node/1782136/pakistan

“Pakistan’s policy of early easing of lockdowns and opening the economy has diverted export orders from China, India and Bangladesh to Pakistan,” she said. “The exports in November 2020 have broken a nine-year record.”

Malik said the industry was currently running at 110 percent capacity, with export orders until June 2021.

Waheed Khaliq Ramay, chairman of the Power Looms Association of Pakistan, said factory owners were “desperately” searching for workers as “almost all power looms in Pakistan, and particularly in Faisalabad, were running at full capacity.”

“Those that were closed since 2016-17 and before are now back in business and continuously expanding,” Ramay said.

Faisalabad has around 300,000 fabric-manufacturing power looms, of which more than 50,000 were closed in 2016-17 due to a long-running energy crisis. But industry officials say the industry is picking up once more, with 40,000 new power looms being set up to meet growing demand, Malik said.

The textile industry, which comprises 46 percent of the total manufacturing sector and provides employment to around 25 million Pakistanis, contributes 8.5 percent to the GDP, according to the Pakistan Board of Investment. It also contributes 60 percent to overall exports and is one of the major earners of foreign exchange for Pakistan.Despite a global economic slowdown due to COVID-19, Pakistan’s textile sector reached $6 billion exports in the first five months of current fiscal year (July-November 2020), which is 62 percent of total exports (worth $9.7 billion) and almost 5 percent higher compared to the same period last year, official data shows.

“Incentives and export facilitations have played a big role in making Pakistan a competitive exporting country,” Malik said.

-

Comment by Riaz Haq on March 3, 2021 at 11:54am

-

Bangladesh achieved an economic landmark last week, when the United Nations’ Committee for Development Policy recommended that the country graduate from the least-developed-country categorization that it has held for most of the 50 years since it became independent.

https://www.wsj.com/articles/bangladesh-is-becoming-south-asias-eco...

Bangladesh is notable in South Asia for being the closest proxy for the successful development models seen at various stages in South Korea, China and Vietnam. Export-led development has the best modern track record of moving countries from very low income levels into middle-income status.

Bangladesh’s exports have risen by around 80% in dollar terms in the past decade, driven by the booming garment industry, while India and Pakistan’s exports have actually declined marginally.

There are other factors in the country’s favor as far as its development model goes: a very young demographic structure, a continued competitive edge in terms of wage levels, strong and rising female labor-force participation especially relative to the rest of South Asia.

There are some meaningful potential hindrances, however. For one, Bangladeshi export growth is well below that of Vietnamor Cambodia, where exports have more than tripled and more than doubled respectively over the past 10 years. India’s exports boomed in the early 2000s and then stagnated, so a continued upward trend isn’t guaranteed.

The next step for Bangladesh would be to transition toward higher-value forms of manufacturing and exporting, as Vietnam has done. Its export industry is still overwhelmingly focused on garment manufacturing. The country’s economic complexity, ranked by Harvard University’s Growth Lab, is 108 out of the 133 countries measured. That is actually lower than it was in 1995.

Bangladesh also finds itself, like India, outside of major Asian trade blocs. It isn’t a member of the Association of Southeast Asian Nations, or the Regional Comprehensive Economic Partnership or the Comprehensive and Progressive Trans-Pacific Partnership. Diversifying its manufacturing exports would require greater participation in intra-Asian supply chains—and probably a closer economic relationship with its neighbors to the east.

Caveats aside, Bangladesh’s exit from LDC status is probably a sign of further progress ahead—and a shot across the bow of other South Asian neighbors taking a very different approach to development.

-

Comment by Riaz Haq on November 8, 2021 at 12:29pm

-

Bangladesh’s monthly minimum wage lowest in Asia-Pacific region: ILO

Neighbouring country Pakistan topped the chart in South Asia with a monthly minimum wage level of $491, while India has the second lowest minimum wage level of $215

https://www.tbsnews.net/economy/bangladeshs-monthly-minimum-wage-lo...

The monthly minimum wage level in Bangladesh was $48 or around Tk4,070 in 2019 – the lowest among all nations in Asia and the Pacific region, reveals the Global Wage Report 2020–21.

Published by the International Labour Organization (ILO) on Wednesday, the report calculated the "Gross Monthly Minimum Wage Levels in Asia and the Pacific" using the Purchasing Power Parity (PPP) values.

Globally, Bangladesh ranked fifth from the bottom among 136 countries. Neighbouring country Pakistan topped the chart in South Asia with a monthly minimum wage level of $491, while India has the second lowest minimum wage level of $215 in the region, it says.

In the Asia and the Pacific region, the median (average) minimum wage is $381, which is $333 or around Tk18,250 higher than that of Bangladesh. However, the ILO report excluded agriculture and domestic workers while calculating Bangladesh's monthly minimum wage level.

Commenting on the matter, Policy Research Institute's Executive Director Dr Ahsan H Mansur said, "Actually, minimum wage is only applicable to Bangladesh's garments sector, and it has no application in any other ones. Elsewhere, the minimum wage is even lower.

"So, the report is not a real reflection of the true picture, and if the minimum wage is increased artificially, it would not be very beneficial at all. If we increase the minimum wage level only in a particular segment and exclude the whole economy, there will not be any positive."

He added that Bangladesh does not have a minimum wage level in every sector and for every job, so the comparison made by the ILO is not appropriate.

Additionally, the report mentions that Bangladesh's actual monthly minimum wage was only $18 last year.

In the region, Australia has the highest monthly minimum wage of $2,166 in terms of PPP, followed by New Zealand with $2,126 and South Korea with $2,096.

What is the situation in South Asia?

Nepal is following the chart-topper Pakistan with a minimum wage level of $396 in this region, and Afghanistan is just behind Nepal with $306.

At the bottom end, Bangladesh and India is followed by Sri Lanka, which has the third lowest minimum wage level of $247 in the South Asia region.

Bangladesh revises the minimum wage every five years and last did it in December 2018. The report mentions that out of 149 countries, only Bangladesh and Angola have not yet made any schedule for the next adjustment of the minimum wage.

About the issue, Dr Mansur said, "Amid this Covid-19 crisis and the ongoing export situation, if the minimum wage is increased now, unemployment may rise further. Instead, we should focus on increasing our labour productivity.

"Productive workers can get an annual pay rise automatically."

Globally, the median value of gross minimum wages for 2019 is $486 per month, indicating that half of the countries across the globe have minimum wages set lower than this value, and half have minimum wages set higher.

Largest decrease in real minimum wage

Bangladesh has seen 5.9% decrease in real minimum wage growth annually, from the period between 2010 and 2019. This was the largest decrease in Asia and the Pacific region.

Meanwhile, the neck and neck RMG export competitor Vietnam (11.3%) observed the highest increase of real minimum wage growth.

Addressing the issue, Dr Mansur said, "This is not desirable and a matter of deep concern too."

On a separate note, the annual labour productivity growth increased by 5.8% in Bangladesh, compared to 5.1% of Viet Nam for the same period.

Twitter Feed

Live Traffic Feed

Sponsored Links

South Asia Investor Review

Investor Information Blog

Haq's Musings

Riaz Haq's Current Affairs Blog

Please Bookmark This Page!

Blog Posts

Russian Hackers Steal Indian Military Secrets From Pakistani Cyber Spies

Hackers linked to Russian intelligence have stolen Indian military data from cyber spies believed to be working on behalf of the Pakistani state, according to an assessment by Microsoft researchers. All those involved are part of what are known as "advanced persistent threat" (APT) organizations in their respective countries. TechTarget defines "Advanced Persistent Threat (APT)…

ContinuePosted by Riaz Haq on December 8, 2024 at 8:00am

IDEAS 2024: Pakistan Defense Industry's New Drones, Missiles and Loitering Munitions

The recently concluded IDEAS 2024, Pakistan's Biennial International Arms Expo in Karachi, featured the latest products offered by Pakistan's defense industry. These new products reflect new capabilities required by the Pakistani military for modern war-fighting to deter external enemies. The event hosted 550 exhibitors, including 340 international defense companies, as well as 350 civilian and military officials from 55 countries.

Pakistani defense manufacturers…

ContinuePosted by Riaz Haq on December 1, 2024 at 5:30pm — 3 Comments

© 2024 Created by Riaz Haq.

Powered by

![]()

You need to be a member of PakAlumni Worldwide: The Global Social Network to add comments!

Join PakAlumni Worldwide: The Global Social Network