PakAlumni Worldwide: The Global Social Network

The Global Social Network

Lower Import Duties Rattle Pakistan's Mobile Handset Makers

Pakistan Federal Board of Revenue has recently announced that “Sales Tax and Income Tax at import stage has been drastically reduced in case of smartphones of Rs15,000 or below". This action was apparently taken after Digital Pakistan Initiative led by Tania Aidrus asked for it. It has come under fire from the country's nascent mobile phone and smartphone manufacturing industry which is producing low-cost mobile phones. Pakistan's mobile handset market is the 8th largest in the world. Current annual demand is for about 40 million units of which 13 million are assembled in Pakistan while the rest are imported, according to a report by Dunya News. The import bill for Fiscal Year 2020 is expected to be about $1.2 billion. Boosting it will save billions of dollars of precious foreign exchange. It will create tens of thousands of jobs and spawn new auxiliary manufacturing industries for chargers, headphones, USB cables, cases, etc. In future, Pakistan could become a significant exporter of mobile handsets.

Mobile Phone Demand:

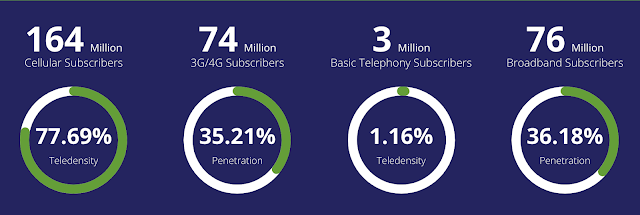

There are currently 164 million mobile phone users in Pakistan, the 8th largest in the world. The current annual demand for mobile phones in the country is estimated at about 40 million units, according to Pakistan Telecommunication Authority (PTA). The fastest growing demand is for 4G smartphones.

According to Pakistan Bureau of Statistics, mobile-phone imports (HS Code: 8517.1219) reached $498 million in 5 months period from July to November 2019, 64% jump over the prior year. Fiscal 2019-20 imports are expected to reach $1.2 billion.

Earlier, the growth rate for 4G handsets jumped from 16% in 2018 to 29% in 2019. Imports of mobile handsets soared 69% from $ 364 million in 2018 to $ 615.7 million in 2019. Pakistan is world's seventh largest handset importer and the 8th largest mobile phone market.

Domestic Manufacturing:

Pakistan Telecommunication Authority (PTA) has granted permission to 26 local companies for manufacturing out of which 15 are currently in production. Among those currently producing mobile handsets in Pakistan are: E-Tachi, GFive, Haier, Infinix and Tecno. They are producing 13 million mobile phones.

Domestic manufacturers claim that they can meet 80% of demand for mobile handsets over the next 2 to 3 years if they are sufficiently protected by higher tariffs on imports.

Domestic mobile phone manufacturing industry will save billions of dollars of precious foreign exchange. It will create tens of thousands of jobs and spawn new auxiliary manufacturing industries for parts, chargers, headphones, USB cables, cases, etc. In future, Pakistan could become a significant exporter of mobile handsets.

Summary:

Pakistan's mobile handset market is the 8th largest in the world. Current annual demand is for 40 million units. Domestic plants produce 13 million units while the rest are imported. The import bill for Fiscal Year 2020 is expected to be about $1.2 billion. The country's nascent mobile handset manufacturing industry fears a serious early setback if the FBR decision to lower duties on imports of foreign made mobile phones is not reversed. It is being blamed on Tania Aidrus, Prime Minister Imran Khan's advisor on Digital Pakistan Initiative, who would like to increase availability of mobile handsets. Domestic mobile phone manufacturing industry will save billions of dollars of precious foreign exchange. It will create tens of thousands of jobs and spawn new auxiliary manufacturing industries for chargers, headphones, USB cables, cases, etc. In future, Pakistan could become a significant exporter of mobile handsets.

Related Links:

Public Sector IT Projects in Pakistan

Pakistan's Gig Economy 4th Largest in the World

Afiniti and Careem: Tech Unicorns Made in Pakistan

Pakistani American Heads Silicon Valley's Top Incubator

Silicon Valley Pakistani-Americans

Digital BRI and 5G in Pakistan

Pakistan's Demographic Dividend

Pakistan EdTech and FinTech Startups

State Bank Targets Fully Digital Economy in Pakistan

Fintech Revolution in Pakistan

The Other 99% of the Pakistan Story

-

Comment by Riaz Haq on March 16, 2020 at 7:00pm

-

BR Research: Start by telling us about this new venture for mobile handset manufacturing in Pakistan.

https://www.brecorder.com/2020/03/11/578939/an-interview-with-aamir...

Aamir Allawala: This project, I would say, marks the beginning of CPEC Phase II and it is a clear signal that Pakistan is open for big foreign investment. In the smartphone industry, this is the first Chinese investment in Pakistan. I would first like to give you a little bit of a background about us. Our company Tecno Pack has been in business since 1971. We have been manufacturing automobile parts (for cars, tractors and motorcycles) over the past few decades, and we did a recent Joint Venture project with Suzuki Japan with an investment of Rs2.87 billion. We employ about 2100 workers at our 5 manufacturing plants. Over the years, we have ventured into electronics manufacturing as well. We found this opportunity for mobile manufacturing, saw the wide gap that exists in the market, and immediately grabbed it. This brought our new partnership with Transsion Holding which is a Chinese manufacturer of mobiles phones, one of the top in the world in terms of volumes with sales of over 124 million in 2018. Apart from China, it has factories in India, Bangladesh, Ethiopia and with this new investment, Pakistan.

BRR: What is the total investment, your equity and the current assembling capacity of mobile phones?

AA: The total investment is Rs480 million and we have a 60:40 arrangement with Transsion China. Currently we are operating three production lines with a capacity to assemble 3 million smartphones every year. In terms of human resource, we have on board 750 skilled workers, 70 engineers and 9 Chinese experts.

BRR: How big is the mobile phone market in Pakistan and what is the potential here?

AA: There are 164 million mobile subscribers. The handset market size is about 40 million units with 27 million units currently being imported and 13 million (which are mostly 2G) manufactured locally in the country. These are feature phones and we believe the future is smart. If we had to put a number to it, the potential handset market size should be over 60 million units annually. This would make us one of the top 10 handset markets in the world.

This is a big space. We need a new plan for Pakistan where we are not just importing and consuming, but also contributing to the production and creating jobs. The first step to do that is to get into industrial assembly. We can train more skilled workers and build an industry foundation by adopting phase-wise localization. As localization grows, technology transfer happens and industry expands. Mobile phone manufacturing can be that industry.

We have examples from countries where the mobile phone industry has transformed the whole economy Look at Samsung in Vietnam. In 2014, Samsung set up its first factory in Vietnam and today, Samsung has an investment of over $17 billion in the country. It contributes 28 percent in Vietnam's GDP, it has more than 100,000 employees and in terms of mobile phones, nearly $37 billion of exports are made by Samsung from Vietnam. When other countries saw Vietnam's growth, they have raised their hands to participate.

India is bidding to become the next China. In mobile phones, within three years of announcing a mobile manufacturing policy, they have 268 factories producing mobile phones and accessories with 61 brands in production including Samsung, Apple, Oppo, Vivo etc. They have now become the second largest mobile producer in the world after China. Last year India produced 225 million units and 95 percent of mobile phones sold in India are made in India.

Then there is Bangladesh. It started final product assembly–which is the first step– in 2017. Brands include Samsung, Oppo, Vivo, Infinix etc. and it is now assembling mobile phone motherboards as well.

BRR: Your current goal is to tap the existing market in Pakistan, is that correct? What is your expansion plan to make that happen?

AA: The domestic market is huge and this is only the beginning. Our expansion plan is already in place. The new investment for Phase-II is Rs 336 million, which will allow us to assemble 13 million smartphones in Pakistan every year on 13 production lines. Once this capacity takes off, we can provide skilled jobs to over 4500 people, which would include 300 engineers. We have made the preparations and are good to go.

BRR: In terms of assembly and localization, what are your targets?

AA: At the moment, we are doing final product assembly. At this level, the local value we will add is 8 percent. This is where all the parts are brought in and we assemble them at our factory. In Phase-II, we will be providing product packaging, chargers and hands-free device. Subsequently, in Phase-III, we would localize plastic and material components, in Phase-IV, we can start the assembly of motherboards within the mobile phones. These motherboards have micro-components whose assembly requires technology and technical skills. In Phase V, we can localize batteries and displays. The combined localization we can reach is 49 percent of the value for a smartphone, which we can see materialize in the next four years.

Transsion has promised us that they will bring their suppliers of raw materials here so we can actually develop the entire smartphone value chain in the country, not just the assembly of final product.

BRR: Is the regulatory environment in the country conducive to mobile assembly and localization–especially now that the new mobile phone policy is being put in place?

AA: One positive development has been the implementation of Device Identification, Registration and Blocking System (DIRBS) recently, which has made the illegal grey market of smartphones completely impossible. The PTA has also given licenses to 26 companies for local manufacturing.- of which 10-12 are currently operating. These have been positive steps but this is a nascent industry that requires incentives under a policy. There should be a reasonable differential between the import of assembled phones i.e. Completely Built Unit (CBU) and the import of parts and components. The draft of the smartphone policy introduced by the EDB includes some important incentives. The Completely Knocked Down (CKD) kits imported by local manufacturers are exempted from regulatory duties as well as custom duties. We strongly believe that there also should be a sales tax exemption on these kits (for phones value up to $200), which is missing. This will allow a reasonable differential between imported CBU phones and CKD kits, which would enable domestic manufacturing.

-

Comment by Riaz Haq on May 22, 2020 at 5:21pm

-

PTI govt approves mobile phone manufacturing policy

https://tribune.com.pk/story/2226608/2-pti-govt-approves-mobile-pho...

The mobile phone manufacturing policy would ensure “localisation and indigenisation of parts of mobile phones”, said the finance ministry.

“The country faces a serious security threat as there is a growing concern of Indian-manufactured smartphones using other countries’ Type Allocation Code within the initial eight-digit portion of the 15-digit International Mobile Equipment Identity (IMEI) used to uniquely identify wireless devices,” said the information technology ministry.

It may be technically very difficult for Pakistani authorities to identify and restrict the import of Indian assembled/manufactured smartphones with other countries’ IMEI numbers, it added. Samsung is currently operating the world’s largest mobile handset factory in India.

Under the Mobile Device Manufacturing Policy, parts of mobile handsets will be used in the entire range of mobile handsets produced in Pakistan instead of being limited to a particular model. The policy will have a positive impact on allied industries including packaging and plastic. The expected manufacturing of high-end brands would give the domestic industry an opportunity to become part of the global value chain, said the finance ministry.

Tax incentives

The ECC approved the removal of regulatory duty charged on the import of completely and semi-knocked down (CKD/SKD) manufacturing devices by Pakistan Telecommunication Authority (PTA)-approved manufacturers under the Input/Output Co-Efficient Organisation (IOCO)-approved import authorisation. The ECC approved the abolition of fixed income tax of up to Rs1,740 per handset on the CKD/SKD manufacturing of mobile devices having an import value of up to $350.

However, it increased the fixed income tax on the $351-500 category handsets by Rs2,000 or 37% to Rs7,400 per set. Similarly, the mobile sets having an import value of more than $500 will be subject to an additional Rs6,300 or 68% income tax, bringing total per handset income tax to Rs15,570.

The ECC approved the removal of a fixed sales tax on the CKD/SKD manufacturing of mobile devices.

PTA will also allow activation of handset manufacturing in the country under import authorisation under the special category to eliminate misdeclaration in the parts category at the import stage.

The activation of completely built units (CBUs) imported through notified routes after payment of all levied duties and taxes, as fixed by the government from time to time, will continue till further amendment.

The government also approved a research and development allowance of 3% for local manufacturers on the export of mobile phones. The locally assembled and manufactured phones will be exempt from a 4% withholding tax on domestic sales.

The government will maintain tariff differential between CBU imports and CKD/SKD manufacturing till the expiry of the policy. The domestic industry will ensure the use of local parts and components as per the road map in the draft policy.

-

Comment by Riaz Haq on October 21, 2020 at 4:10pm

-

#Pakistan Business Council warns accession to the World Trade Organization’s (#WTO) treaty of free #trade of #IT products to break #cellphone & other #electric products #manufacturing dream. #technology #Smartphones #Electronics #informationtechnology https://www.thenews.com.pk/print/729918-pbc-warns-wto-treaty-to-bre...

PBC, in a report on Thursday, expected the information technology agreement (ITA) to cause jobs and revenue losses and suppress potential for exports.

“The ITA will result in a net loss to the economy by replacing locally manufactured products with imported ready-to-sell products in the ITA listed categories,” said the council. “This will not only undermine the efforts to encourage investment by electronics manufacturers in Pakistan, but it will also cost Pakistan its independence to apply policy interventions to gradually increase its product space for exporting electronic products.”

The agreement aims to eliminate custom duties and reduce non-tariff measures which restrict trade in IT and electronic products. The goal is to increase global trade and competition in IT goods and services, increase adoption of technology and spur innovation in the sector. ITA accounts for 97 percent of world trade in IT and electronic products with trade volume of $3.7 trillion in 2019.

“There is an inconclusive evidence to suggest ITA is an appropriate avenue to expand a country’s capability in manufacturing and exporting electronics and IT products,” said the PBC. “Whilst counties that a signatory to the ITA have increased their IT and electronic product exports, non-signatories have also increased exports manifold.”

India and Bangladesh use cascading tariff structure to increase localisation and manufacturing of electronics in their countries. India, being signatory to the agreement, is facing international disputes in the WTO for adopting policies for localising manufacturing of electronics, claiming them to be against the ITA protocols.

The information technology agreement is not bound on any member country of the WTO. It has so far been signed by advanced economies that already have strong exports base of IT products.

Pakistan’s imports of ITA related products rose six-fold between 2003 and 2019, significantly higher than the global average. The imports recorded a compound annual growth rate of 13.2 percent during the period. The growth rate was much higher than the global average of 8.4 percent, according to the PBC

The business council said the country has experienced de-industrialisation due to policies that discourage manufacturing and make it easier to import finished products.

PBC said allowing across the board zero duty on components and finished, ready-to-sell electronics, will result in closure of existing manufacturing units, and also discourage additional investments in production facilities for electronics.

“By disallowing cascading of tariffs under ITA, and removing the advantage for local manufacturing, for example as envisaged in the mobile phones manufacturing policy, companies such as Samsung may lose interest to invest in smartphone assembly in Pakistan,” it said. “Not only will this have an adverse impact on the external account, Pakistan will also miss opportunities to acquire technologies in manufacturing electronics by reducing the chances of foreign companies to enter Pakistan.”

The council said the Federal Board of Revenue estimated revenue loss of Rs3.5 billion from 105 tariff lines following Pakistan’s accession into the ITA.

Though imports of ITA-based products are a good proxy measure of technological adoption and accession to ITA will lead to zero-rated imports of electronics, it will further delay development of IT manufacturing sector.

-

Comment by Riaz Haq on October 21, 2020 at 4:15pm

-

Local mobile phone manufacturers have urged the Ministry of Industries and Production to implement Cabinet decision of exempting four percent withholding tax on the sale of Pakistan made handsets.

https://www.brecorder.com/news/40022762/4pc-wht-exemption-on-local-...

In a written letter to the Engineering Development Board (EDB) the Pakistan Mobile Phone Manufacturers Association (PMPMA) while urging the Ministry to exempt the sales of local manufactured cell phones from 4 percent withholding tax has requested for the implementation of June 2, 2020 Cabinet decision.

The letter was sent to Chief Executive Officer (CEO) EDB by PMPMA, copies of which have also been sent to Industries Minister and other Ministries, the Association revealed.

According to official sources the PMPMA since the approval of the mobile device manufacturing policy in June 2020, has repeatedly requested the relevant officials for the implementation of the policy in letter and spirit, so that they can optimise their operations but so far the ministry does not appear to be serious in implementing the policy.

This was the industry’s perception after the meeting held in the office of Minister of Industries on 3rd September, 2020 and subsequent follow up meeting with the Chairman and CEO (EDB) held in Lahore on 18 September, 2020.

Pakistan Mobile Phone Manufacturers Association deliberated the issue and raised the following five point opinion in the letter: (i) the exemption of 4 percent withholding tax on local sales of locally manufactured mobile phones is an integral part of the mobile device manufacturing policy approved by the federal cabinet on 2nd June, 2020.

(ii) The exemption is absolutely critical to provide a level playing field to the local industry which consists of more than 15 manufacturers and provides employment to over 7 to 10 thousand. Moreover the local cell phone manufacturers are planning to expand their plants to produce more handsets to meet the local demand for mobile phones.

(iii) If the exemption, already approved under the MDMP, is not notified, it shall disturb the differential envisaged under the MDMP between the duty and taxes on CKD/SKD kits of locally manufactured mobile phones as compared to CBU imports into the country.

(v mobile phone industry is strategic a sector which, if properly incentivised, can provide employment opportunities to over 200,000 Pakistanis, and within a short period of time, create export opportunity worth billions of rupees.

-

Comment by Riaz Haq on October 23, 2020 at 11:35pm

-

Infinix #mobile phone factory in #Karachi is producing around 3 million mobile devices per year. It is reshaping the #smartphone experience in #Pakistan with its latest offerings. Here's how - Sponsored - DAWN.COM. https://www.dawn.com/news/1586440

Infinix, a leading smartphone brand in the Pakistani market has caused a stir in the world of tech in a short period of time.

Leading the future in the smartphone world in Pakistan, the brand has set new benchmarks in innovation-led manufacturing through cutting-edge technology, exquisitely designed dynamic smartphones, and conquered global life experiences with a winning combination of technology tossed with fashion.

Infinix is well known for being bold and forward-leaning.

Instead of playing it safe, it has taken the risk and moved fast. Instead of waiting for others, it has set the direction for competitors.

The tech innovator has completed five strong and successful years in the market, growing from strength to strength, becoming the most loved, and trusted choice in Pakistan; a legendary brand that challenges the norms with devices explicitly designed for the country's youth to learn about the opportunities and challenges of global expansion, focusing on fast-moving high-tech space.

Here's a rundown of Infinix’s journey of becoming a success story in Pakistan.

How it all began

The journey started in 2013 with a strategy of complete line of mobile devices.

With the SURF series 39's initial release, the brand introduced ‘ALPHA’ and unveiled the high-end ‘Marvel series’ which received fantastic response. The same year, Infinix broke through the market with the launch of the ‘Zero series’. Its popularity with the masses instantly made it a premium smartphone brand in the emerging markets.

The company's success depended not only upon the quality product but also the reliability & benchmark it had set. During its trailblazing tenure in 2015, the brand witnessed top sales record for any single product with the launch of ‘HOT’. Simultaneously, the ‘NOTE series’ was introduced to cater to the business and daily functionality for consumers.

Aware of the nature of its millennial audience and financial restraints, Infinix took a giant leap in 2016 by introducing a winning combination of tech and fashion, i.e. the ‘S series.’

Infinix has currently been marked as the largest mobile phone production and assembly company in Pakistan. The existing factory produces 3 million units per year.

Exquisite design

Infinix innovations have a clear purpose: represent infinite possibilities and distinctive characteristics.

Influenced by French designs and investments, they make life better and easier. The designs are more personal, intelligent, and deliver an experience that flows seamlessly and continuously wherever you go. It combines power and functionality, whether you are at work or play at home or away.

Tech innovation

A brand that envisions phones as an expression of self-discovery and has struck a chord with users who prioritise fashion and technology through daily interactions, Infinix's range of intuitive products has become a lifestyle by default, representing intelligent and trend-setting experiences around the world.

In a developing country like Pakistan, smartphones, in general, are unable to reach the masses due to their high price points. Infinix designs smartphones for techies who are on the lookout for stylish and aesthetic designs at the best value for money.

Presence around the globe

The company has its footprints across the world; however, its contemporary design, the need for digital technology, and effective functionality have made it incredibly popular across more than 70 countries in South East Asia, South Asia, Africa, Latin America, and the Middle East.

-

Comment by Riaz Haq on November 2, 2020 at 1:26pm

-

Interest in cellphone assembly grows as smuggling falls

PTA has so far permitted 24 companies to assemble handsets in Pakistan

https://tribune.com.pk/story/2186936/interest-cellphone-assembly-gr...

Last month, Pakistan began local manufacturing of mobile phones, which is expected to open further avenues of investment in the country and create employment opportunities.

Chinese company Transsion Holdings and Pakistan’s Tecno Group have formed a joint venture called Transsion Tecno Electronics Ltd (TTE) with the Chinese company having 40% shareholding while the remaining 60% stake is held by the Pakistani firm.

The joint-venture company – the first 3G/4G smartphone manufacturing facility in Pakistan – has initial capacity to produce 1.8 million units annually on a single-shift basis with over 800 skilled workers below 30 years of age.

“The value of Pakistan’s mobile phone market stands at Rs366 billion, which is even higher than the value of the auto sector which is around Rs360 billion,” remarked TTE CEO Asif Allawala. “Interestingly, the government drafts policies conducive for the auto sector but ignores the mobile phone industry.”

He added that the industry would not be able to sustain much longer if the import of smartphones remained cheaper than local manufacturing.

Mobile industry worldwide

The mobile phone sector ranks among the five biggest industries in the world with sales revenue of $522 billion and over 6 billion devices sold annually.

China has been enjoying the label of being the global hub of handset manufacturing since 2010. The country exports mobile phones worth over $150 billion a year.

However, the handset production is now moving out of China due to rising labour cost and a prolonged trade war with the US.

“On average, Chinese labour costs $600 per month while Pakistan’s labour is much cheaper at only $120 per month,” said the TTE CEO.

However, Pakistan still remains far behind in the race of providing cheap labour force as many other Asian nations are increasingly luring mobile phone assembly companies by offering low-cost workers.

Most of the demand for mobile phones stems from Asia and Africa while markets in Europe and North America are on a saturation point, hence, their trend remains more or less flat each year. This provides a further incentive to the mobile phone manufacturers to relocate their units to Asian nations.

According to Statista, 1.5 billion units of smartphones were sold in 2019 worldwide. The number had been 122 million in 2007.

Pakistan’s market

Pakistan has 164 million cellular subscribers out of a population of 207 million. The country ranks seventh among world’s largest handset importers.

Alone in 2015, the country saw 114 million mobile subscriber identity modules (SIMs) sold with 46 million supporting 3G/4G while 68 million were 2G subscribers.

“Due to its mammoth size, no global brand can ignore Pakistan’s market,” said TTE Director Aamir Allawala. “The country’s annual market size, including 2G, 3G and 4G, is estimated at 34 million units.”

That meant the country’s demand for mobile phones remained in millions every year as a cellphone, especially smartphone, was changed by many consumers after two to three years, he said.

Pakistan Telecommunication Authority (PTA) has successfully tackled the handset smuggling. Government’s endeavours to curb grey channels have yielded results as the country recorded 110% increase in legally imported mobile phones in 2019 compared to 2018.

“According to analysis, an increase of 110% has been seen in legal import of devices from the formal channel,” confirmed a PTA spokesperson to The Express Tribune.

Over more than a year ago, the government started blocking the mobile sets (smuggled phones) that were not approved by PTA with the help of Device Identification, Registration and Blocking System (DIRBS).

-

Comment by Riaz Haq on December 15, 2020 at 6:09pm

-

#Pakistan on brink of inking #industrial accord with #China for industrial cooperation to develop B2B joint ventures, build Special Economic Zones (SEZs) and industrialization under the second phase of #CPEC. #economy #industry #business #manufacturing https://www.thenews.com.pk/print/759243-pakistan-on-brink-of-inking...

“Prime Minister Imran Khan has already given approval to it. After consultation, both the countries will formally sign this framework agreement,” a senior official said.

On Tuesday, representatives from both the countries held the fifth meeting of Joint Working Group (JWG) on industrial cooperation under CPEC through video conference.

The Chinese side appreciated the efforts undertaken by Pakistan to elevate the MoU (Memorandum of Understanding) on industrial cooperation into a Framework for an increased cooperation under CPEC and agreed to continue consultation for its signing at the earliest. They also hailed the idea of joint industrial diagnostic studies followed by an action plan.

Khashih-ur-Rehman, Additional Secretary/Executive Director General, Board of Investment (BOI) and Ying Xiong, Director General, National Development & Reform Commission (NDRC), China co-chaired the meeting. Representatives from line ministries, provincial governments, and embassies attended the meeting.

Rehman remarked that elevation of the MoU on IC (Industrial Cooperation) between Pakistan and China into a comprehensive framework would create new avenues for strengthening industrial cooperation under CPEC which is also open to third party participation.

Cooperation would likely enhance B2B and project to project (P2P) ties, balance and modernise existing industry, expedite SEZs development and promotion, seek technical and financial assistance from China, increase production capacity, and facilitate businesses with support of financial institutions from both sides, etc, he added.

Asim Ayub, Project Director of Project Management Unit (PMUC-CPEC-ICDP) on Industrial Cooperation of BoI, appreciated the Chinese side for accepting the Draft Framework Agreement shared by the Pakistani side in early November 2020.

Early signing of the Framework Agreement on IC would help both sides achieve maximum objectives of CPEC in line with its long-term Plan, Ayub said, adding that immense efforts had been ensured by Pakistani to devise the Draft Framework, taking all the provinces and other stakeholders on board and final approval of the Honorable Prime Minister was also obtained accordingly.

He stressed a Framework Agreement was the need of the hour for a measurable impact with regards to Industrial Cooperation, SEZs, Business to Business (B2B) and People to People (P2P) collaboration.

Ayub said Pakistan highly regarded the idea of Industrial Diagnosis by the Chinese side and extended its highest support to the group of experts from CIECC for the Textile Industrial Diagnosis last year. However, he was of the view that the Industrial Diagnosis needed to be carried out in a joint manner involving experts from both sides who might submit the Diagnosis Report to the JWG along with an Action Plan that would be imperative for the respective industrial sector.

The meeting also discussed progress made on Rashakai, Dhabeji, Alama Iqbal Industrial City, and Bostan SEZs under the CPEC, the revival project of Pakistan Steel Mill, China Pakistan Young Workers Exchange and Cooperation, and Karachi Coastal Comprehensive Development Zone.

-

Comment by Riaz Haq on December 21, 2020 at 10:40am

-

Smartphones Policy to Create 50,000 Jobs in the Next Few Years

https://www.phoneworld.com.pk/smartphones-policy-to-create-50000-mo...

There are about 16-18 cell phone manufacturers operating in Pakistan and a few others are coming. These plants are providing jobs to about 25,000 people – mostly young boys and girls. The industry experts are of the opinion that 50,000 more jobs will be created in the segment in the next few years. Some say that 70 per cent of jobs would be for women.

One auto parts manufacturer in Karachi delved into the smartphone assembling in the early days and is producing around 500,000 units a month for the local market. He is confident that the capacity would double in a year and the production will reach a million units a month.

Another player in Lahore is making a state-of-the-art mobile assembly facility which is going to be operational in January 2021. The aim is to reach 500,000 units a month by March-April; and by June-July, the facility will start expanding. The aim is to reach a million units a month by the end of 2021. The assembler is the biggest importer of smartphones in Pakistan and is doing backward integration.

The mobile phone formal industry is growing fast. In yesteryears, around 800,000-900,000 units used to be imported a month in Pakistan through formal channels. After the induction of Device Identification, Registration and Blocking System (DIRBS), illegal imports of the phone is no longer possible. Due to this and lockdown, smartphone imports went up to 2-2.2 million in June 20. Overall, the monthly average import in Pakistan is standing around 1.3-1.5 million units a month in 2020.

Majority of the phones are in the category of $200 or low, and all these would probably be assembled in Pakistan within a couple of years. Any company that would not decide to assemble in Pakistan could be wiped out in the cheap smartphone segment. That could be a worry for Samsung. The company operates in all segments. Its premium phones would keep on coming as imported units – but the segment is small. If the company doesn’t start assembling here, it risks losing market share. it is still mulling on the assembly idea.

Apart from Samsung, big Chinese brands such as VIVO and OPPO are also weighing options of starting assembly in Pakistan, and VIVO could be one big player in a few years in the local market assembling. Once big companies come in and set up units in Pakistan, parts manufacturing may start taking place at home. There will be a huge spillover for the local assemblers.

The smartphone policy is envisaging in stage 1 (2020-21) to start assembling units here – that is happening and credit goes to EDB and Ministry of Industries. In stage 2, the plan is to have a charger, Bluetooth, handsfree, and motherboard (PCB) assembly by 2022. Housing and other plastic parts manufacturing to start in 2023, and stage 4 is to make display and battery by 2025.

For all these steps, big Chinese and Korean players should come and assemble here. PM Imran Khan should take this initiative and talk at the government-to-government level. The ground is being laid. The industry players are charged, the gaps in cellphone and data penetration still exist and the government needs to work on rolling the right infrastructure. The smartphone assembly could well be the first step of Pakistan venturing into the tech hardware.

-

Comment by Riaz Haq on March 6, 2021 at 8:42pm

-

Pakistan: 1.2 million #smartphones manufactured in first two months of 2021. These phones were manufactured at the 33 local #mobile devices assembly plants in #Pakistan. #manufacturing – Gulf News

https://gulfnews.com/world/asia/pakistan/pakistan-12-million-smartp...

The number of smartphones assembled and produced in January and February 2021 indicate a significant increase as compared to the last two years. The country produced 2.1 million smartphone devices in 2020 and 119,639 in 2019, according to Pakistan Telecommunication Authority (PTA).

The country has produced over 25 million mobile devices including 4G smartphones following the successful implementation of PTA’s Device Identification, Registration and Blocking System (DIRBS).

“With the successful execution of DIRBS, the local assembly industry has evolved from infancy to well-growing stage, with significant growth seen in the local assembly of smartphones,” PTA said. The system implemented in 2019 also led to a significant increase in legal imports of mobile devices.

In 2020, Pakistan approved its first mobile device manufacturing policy to attract investment and encourage manufacturers of major cell phone brands to set up plants in Pakistan.

Job opportunities

The policy also aims to create more job opportunities in Pakistan, create smartphone research and development centers and boost the production of electronic equipment in Pakistan.

The government’s offered several tax incentives and abolished withholding tax on locally assembled phones which encouraged the investors to set up companies in Pakistan, says Minister for Information Technology and Telecommunication Syed Amin ul Haque.

Leading smartphone brand Infinix currently has the largest mobile phone production and assembly plant in Pakistan where 3 million units are produced each year.

Vivo, Airlink and Advance Telecom are the three new companies that will soon establish their manufacturing units in Faisalabad, Lahore and Karachi.

PTA also received several mobile device manufacturing applications after finalizing its mobile device manufacturing regulations which “will help create more jobs in this technical sector, as well as enable consumers to buy locally manufactured mobile devices.”

5G connectivity

Pakistan’s telecom sector offers attractive investment opportunities as it boasts of 178 million mobile phone subscribers with 93 million 3G-4G users, according to the January 2021 data.

Pakistan is also set to launch 5G mobile phone connectivity by December 2022 following a successful trial by PTA in February 2021.

The demonstrations included remote surgery, cloud gaming and overview of anticipated 5G technology applications for social and economic development of Pakistan.

“With the successful 5G trial in a limited environment, we believe that this technology will unlock new realities for eHealth, smart homes and cities, agriculture, autonomous vehicles, cloud computing, Internet of Things and Artificial Intelligence” Nadeem Khan, acting CEO of PTCL Group said.

-

Comment by Riaz Haq on March 13, 2021 at 5:56pm

-

#Pakistan Engineering Development Board on #mobile #phone #manufacturing : TranssionTecno’s Itel, Infinix & Tecno are producing 650,000 units per month in #Karachi. Airlink’s plant in #Lahore has production capacity of 500,000 to 800,000 units per month.”

https://www.techjuice.pk/engineering-development-board-begins-works...

In recent news, the Engineering Development Board (EDB), which is a technical arm of the Ministry of Industries and Production (MoIP), has begun working on a framework for the local assembly of tablets, smartphones, and other related mobile accessories in the near future.

The MoIP further stated that the smartphone industry could be larger than the existing automotive industry in the upcoming years due to the high demand for devices across the country. Hence, this report has been formulated in line with the Mobile Device Manufacturing Policy of the Pakistan Telecom Authority, whereas the manufacturing plants fall under the ambit of the EDB.

EDB further added:

“TranssionTecno, Karachi-based company assembles three brands including Itel, Infinix, and Tecno, has increased local assembly from 150,000 units to 650,000 units per month. Airlink Communication Ltd has commenced its test trials at its plant in Lahore, and has the production capacity of 500,000 to 800,000 units per month.”

Moreover, the EDB General Manager Policy Asim Ayaz stated that this policy provides sufficient advantage to the local manufacturing of smartphones especially below the price range of $200 in comparison with imported sets which normally are too costly for consumers to purchase.

Twitter Feed

Live Traffic Feed

Sponsored Links

South Asia Investor Review

Investor Information Blog

Haq's Musings

Riaz Haq's Current Affairs Blog

Please Bookmark This Page!

Blog Posts

Retail Investor Growth Driving Pakistan's Bull Market

Pakistan's benchmark index KSE-100 has soared nearly 40% so far in 2025, becoming Asia's best performing market, thanks largely to phenomenal growth of retail investors. About 36,000 new trading accounts in the South Asian country were opened in the September quarter, compared to 23,600 new registrations just three months ago, according to Topline Securities, a brokerage house in Pakistan. Broad and deep participation in capital markets is essential for economic growth and wealth…

ContinuePosted by Riaz Haq on November 24, 2025 at 2:05pm

PIMEC 2025: Pakistan Plans to Boost Maritime Sector, Blue Economy

Pakistan recently held its second International Maritime Expo and Conference (PIMEC-25) in Karachi where it announced ambitious plans to expand its maritime sector and boost its blue economy. It is an initiative of the Pakistan Navy, organized under the patronage of the Ministry of Maritime Affairs. The country plans to invest a $100 billion in maritime development by expanding…

ContinuePosted by Riaz Haq on November 17, 2025 at 11:30am

© 2025 Created by Riaz Haq.

Powered by

![]()

You need to be a member of PakAlumni Worldwide: The Global Social Network to add comments!

Join PakAlumni Worldwide: The Global Social Network